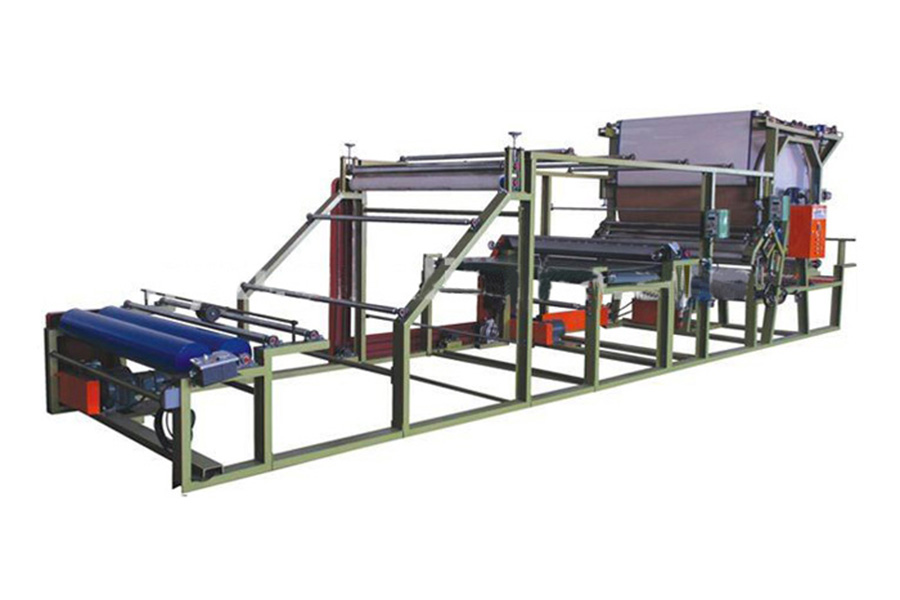

I-laminating umshini wokwenza izicathulo

Impahla yokwenza izicathulo ikakhulukazi yakhiwe izingxenye ezinhlanu ezilandelayo

1.Isikhumba.

Isikhumba siyashintshashintsha kodwa siqinile, siqinile njengoba sithambile.Iyanwebeka, ngakho-ke inganwetshwa kodwa imelana nokudabuka nokuhuzuka.

2.Izindwangu.

Indwangu nayo isetshenziswa kakhulu ukwenza izicathulo.Njengesikhumba, izindwangu zitholakala ngemibala eminingi nezinhlobonhlobo.

3.Ama-synthetics.

Izinto zokwenziwa zihamba ngamagama amaningi ahlukene- Isikhumba se-PU noma i-PU nje, isikhumba sokwenziwa noma ama-synthetics kuphela- kodwa zonke ziyefana ekubeni izinhlanganisela ezimbili ezenziwe umuntu.

4.Irabha.

Injoloba isetshenziswa kakhulu ezicathulweni ukwenza amasoli.

5.Igwebu.

I-Foam iyinto evamile kakhulu esetshenziselwa ukuhlinzeka ngokusekela phezulu kwezicathulo zazo zonke izinhlobo, kungaba isikhumba, indwangu, i-synthetic noma irabha.

Izici Zomshini Wokulahla

1.Isebenzisa iglue esekelwe emanzini.

2.Thuthukisa ikhwalithi yemikhiqizo kakhulu, yonga izindleko.

3. Isakhiwo esimile noma esivundlile, isilinganiso esiphansi sokuhlukaniswa kanye nesikhathi eside sesevisi.

4. I-roller yokondla impahla iqhutshwa yi-cylinder yomoya, ibona inqubo esheshayo, elula futhi enembile.

5. Ifakwe ibhande lenethi elisezingeni eliphezulu lokumelana nokushisa ukuze yenze izinto ezenziwe nge-laminated zixhumane eduze nesilinda esomisayo, ukuthuthukisa umphumela wokumisa nokubopha, nokwenza umkhiqizo owenziwe nge-laminated uthambe, uwasheke, futhi uqinise ukunamathela kokunamathela.

6. Kukhona i-glue scraping blade yokuklwebula iglue ngokulinganayo phezu kwendwangu kanye nomklamo oyingqayizivele wesiteshi seglue usiza ukuhlanzwa kweglue ngemva kokucwenga.

7. Lo mshini we-laminating unamasethi amabili wesistimu yokushisa, umsebenzisi angakhetha isethi eyodwa yokushisa imodi noma amasethi amabili, ukunciphisa ukusetshenziswa kwamandla kanye nezindleko eziphansi.

8. I-surface yerola yokushisisa imbozwe nge-Teflon ukuze ikwazi ukuvikela ingcina encibilikayo eshisayo ukuthi inganamatheli phezu kwerola ne-carbonization.

9. Nge-clamp roller, kokubili ukulungiswa kwesondo lesandla kanye nesilawuli somoya kuyatholakala.

10. Iyunithi yokulawula i-othomathikhi ye-infrared centering ivimbela ngempumelelo ukuchezuka kwebhande lenetha futhi andise ubude bempilo yesevisi yebhande lenetha.

11. Wonke amapayipi okushisa ku-roller yokomisa enziwe ngensimbi engagqwali futhi izinga lokushisa le-roller yokomisa ukushisa lingaba phezulu njenge-160 celcius degree, ngisho ne-200 celcius degree.Ngokuvamile kunamasethi amabili wesistimu yokufudumeza ku-roller yokomisa.Ukushisisa kuzoshintsha ngokuzenzakalelayo ukusuka kusethi eyodwa kuye kumasethi amabili.Iphephile futhi yonga amandla.

12. Idivaysi yokubala kanye nedivaysi yokuhlehlisa ifakwe emshinini.

Kulula ukugcina umshini futhi izindleko zokuwunakekela ziphansi.

13. Ifakwe iyunithi yokulawula i-infrared centering othomathikhi, engavimbela ngempumelelo ukuchezuka kwebhande lenetha, futhi iqinisekise impilo yesevisi yebhande lenetha.

14. Ukukhiqiza okwenziwe ngokwezifiso kuyatholakala.

15. Izindleko zokulungisa eziphansi futhi kulula ukuzinakekela.

Imingcele Eyinhloko Yezobuchwepheshe

| Indlela yokushisa | Ukushisisa ngogesi/Ukushisisa uwoyela/Ukushisisa umusi |

| Ububanzi (Irola Yomshini) | 1200/1500/1800/2000mm |

| Isivinini sokusebenza | 5-45m/min |

| Amandla Okushisa | 40kw |

| Amandla kagesi | 380V/50HZ, 3 isigaba |

| Isilinganiso | 7300mm*2450mm2650mm |

| Isisindo | 3800kg |

FAQ

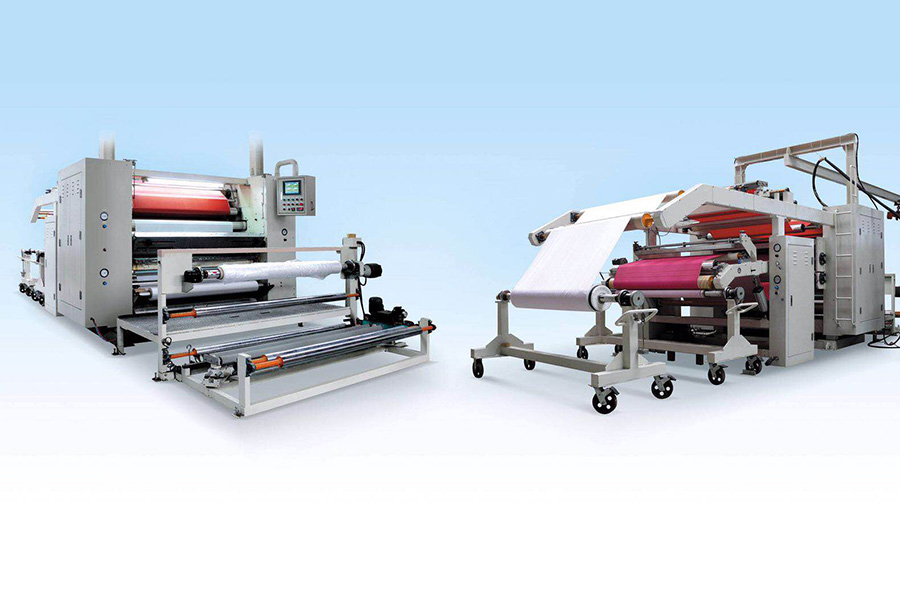

Uyini umshini we-laminating?

Ngokuvamile, umshini wokulambisa ubhekisela emshinini wokugcoba osetshenziswa kakhulu ezindwangu zasekhaya, izingubo, ifenisha, izinto zangaphakathi zezimoto nezinye izimboni ezihlobene.

Isetshenziselwa ikakhulukazi inqubo yokukhiqiza inhlanganisela yezendlalelo ezimbili noma enezingqimba eziningi zezindwangu ezihlukahlukene, isikhumba semvelo, isikhumba sokwenziwa, ifilimu, iphepha, isipontshi, igwebu, i-PVC, i-EVA, ifilimu elincanyana, njll.

Ngokukhethekile, ihlukaniswe nge-adhesive laminating kanye ne-non-adhesive laminating, futhi i-adhesive laminating ihlukaniswa ngeglue esekelwe emanzini, ingcina kawoyela we-PU, iglue esekelwe ku-solvent, iglue ezwela ukucindezela, i-super glue, iglue encibilikayo eshisayo, njll. I-non-adhesive inqubo laminating ngokuvamile thermocompression bonding ngqo phakathi izinto noma ilangabi ukuvutha lamination.

Imishini yethu yenza inqubo ye-Lamination kuphela.

Iziphi izinto ezilungele i-laminating?

(1) Indwangu enendwangu: izindwangu ezilukiwe nezilukiweyo, ezingalukiwe, ijezi, uboya bezimvu, inayiloni, i-Oxford, iDenim, iVelvet, i-plush, indwangu ye-suede, ama-interlinings, i-polyester taffeta, njll.

(2) Indwangu enamafilimu, njengefilimu ye-PU, ifilimu ye-TPU, ifilimu ye-PTFE, ifilimu ye-BOPP, ifilimu ye-OPP, ifilimu ye-PE, ifilimu ye-PVC...

(3) Isikhumba, Isikhumba sokwenziwa, isipontshi, igwebu, i-EVA, ipulasitiki....

Iyiphi imboni edinga ukusebenzisa umshini we-laminating?

Umshini wokulambisa osetshenziswa kakhulu ekuqedeni izindwangu, imfashini, izicathulo, ikepisi, izikhwama namapotimende, izingubo, izicathulo nezigqoko, imithwalo, izindwangu zasendlini, izinto zangaphakathi zezimoto, umhlobiso, ukupakisha, ama-abrasives, ukukhangisa, izinsiza zokwelapha, imikhiqizo yenhlanzeko, izinto zokwakha, amathoyizi. , izindwangu zezimboni, izinto zokuhlunga ezinobungani bemvelo njll.

Ungakhetha kanjani umshini wokugcwalisa i-laminating ofanele kakhulu?

A. Iyini imfuneko yesisombululo semininingwane?

B. Yiziphi izici zezinto ezibonakalayo ngaphambi kokufakwa kwe-laminating?

C. Isetshenziswa kanjani imikhiqizo yakho elaminethiwe?

D. Yiziphi izinto ezibonakalayo ozidingayo ukuze uzuze ngemva kokulanyiswa?

Ngingawufaka futhi ngiwusebenzise kanjani umshini?

Sinikeza imiyalo enemininingwane yesiNgisi namavidiyo wokusebenza.Unjiniyela angaphinde aye phesheya efektri yakho ukufaka umshini futhi aqeqeshe abasebenzi bakho ukuthi basebenze.

Ingabe ngizowubona umshini usebenza ngaphambi koku-oda?

Yamukela abangani emhlabeni wonke ukuthi bavakashele ifekthri yethu nganoma yisiphi isikhathi.