UMQONDO WOMSHINI WE-LAMINATING:

1. Kufakelwa i-gluing kanye ne-laminating yendwangu, i-nonwoven, indwangu, amafilimu angangeni manzi, aphefumulayo nokunye.

2. Kusizwa ukulawula uhlelo lwe-PLC kanye nesixhumi esibonakalayo sokuthinta somshini womuntu, kulula ukusebenza.

3. Ukuqondanisa okuthuthukisiwe konqenqema kanye nemishini ye-scothing, lo mshini unyusa izinga lokuzenzakalela, wonga izindleko zabasebenzi, ukhulula umfutho wabasebenzi, futhi uthuthukisa ukusebenza kahle kokukhiqiza.

4. Nge-PU glue noma iglue esekelwe ku-solvent, imikhiqizo e-laminated inempahla enhle yokunamathela futhi ithinta kahle.Ziyakwazi ukuwasheka futhi zome.Ngenxa yokuthi i-glue isesimweni sephuzu lapho i-laminating, imikhiqizo e-laminated iphefumula.

5. Idivayisi yokupholisa ephumelelayo ithuthukisa umphumela we-lamination.

6. I-cutter yokuthunga isetshenziselwa ukusika imiphetho eluhlaza yezinto ezifakwe laminated.

IZINTO EZILAMINAYO:

1.Indwangu + Indwangu:izindwangu, ijezi, uboya, inayiloni, iVelvet, indwangu yeTerry, iSuede, njll.

2.Indwangu + amafilimu, njengefilimu ye-PU, ifilimu ye-TPU, ifilimu ye-PE, ifilimu ye-PVC, ifilimu ye-PTFE, njll.

3.Indwangu+ Isikhumba/Isikhumba Sokwenziwa, njll.

4.Indwangu + Nonwoven

5.Indwangu Yokuntywila

6.Isipontshi/ Igwebu elinendwangu/ Isikhumba Sokwenziwa

7.Amapulasitiki

8.EVA+PVC

ISETSHENZISWA KAKHULU KU:

1.Imboni Yezindwangu Nezingubo

2.Imboni Yemikhiqizo Yezokwelapha

Imboni ye-3.Izikhwama kanye Nemithwalo

4.Imboni yokupakisha

5.Imboni yezicathulo

6.Imboni Yokuhlobisa

7.Auto ingaphakathi umhlobiso Industry

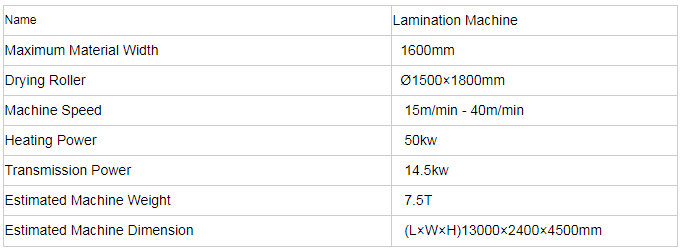

IZICI EZIYINHLOKO:

I-1.Iglue esekelwe ku-Solvent noma i-PU glue iyasebenza emshinini wokugcoba.

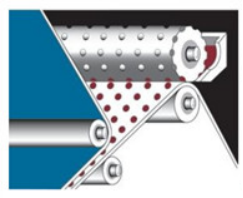

2.Iglue idluliselwa ngokulinganayo endaweni ebonakalayo nge-roller eqoshiwe (ichashazi noma umumo wedayimane noma

ezinye izimo).Ngakho-ke, izinto ezenziwe nge-laminated zithambile, azinamanzi futhi ziphefumula.

3.Inani leglue linqunywa yizici ezimbili: ibanga phakathi kwe-glue roller kanye neglue

i-scraping blade (i-pneumatic control) futhi okwesibili, i-glue roller mesh oyikhethayo emshinini wokugcoba.

I-4.Iphepha elikhethekile elimelana nokushisa okuphezulu kanye ne-antirust Teflon endaweni yokomisa i-roller ivikela

izici zangempela neziyingqayizivele zezinto zokwakha kanye nezici futhi ivimbela iglue ekunamatheleni ku-roller yomshini wokugcoba.

5.Isisetshenziswa esikhethekile sokuqaqa ifilimu kanye nesitholi somugqa wefilimu kufakwa epuletini eliphezulu, kusizakale

ukusebenza kanye nokonga isikhala.I-glue ingadluliselwa kwifilimu noma kwenye indwangu ngaphambi kokubeka i-laminating, izinketho eziningi.

6.Idivayisi yokupholisa ephumelelayo ithuthukisa umphumela we-lamination.

IZICI ONGAZITHANDELA:

1.Kokubili idivayisi yokuvula umoya kanye nedivayisi yokuvala umshini wokugcwalisa i-laminating inokulawula ukucindezeleka okungaguquki kazibuthe.

I-2.Idivayisi ye-hydraulic centering ye-automatic iqinisekisa ukuqondanisa komphetho ku-laminating.

I-3.I-Pneumatic yokwandisa i-shaft ifakwe ukuze kusetshenziswe kalula umshini we-laminating.

I-4.Indwangu Yokusabalalisa Ama-Roller noma Ama-Openers

5.I-Tension Controller

I-6.Gear Transmission izosetshenziswa eduze kwedivayisi yokunamathisela futhi i-roller yokomisa nebhande le-synchrony nakho kungasetshenziswa ukufaka esikhundleni sokudluliswa kwamaketanga lapho kunesidingo, ngakho-ke kuzoba nomsindo omncane ekusebenzeni kwe-laminating mahcine futhi isivinini sizovumelaniswa kahle.

I-7.Ngezindwangu ezinwetshiwe ze-4, isethi yonke yamadivayisi akhethekile izofakwa.

8.Idivayisi ye-Automatic Edge Trimming izofakwa.Uma kudingekile, idivayisi yokukhipha udoti onqenqemeni ngokuzenzakalelayo ingangezwa.

9.Uma kudingeka, i-Siemens noma i-Mitsubishi motors ingasetshenziswa.

I-10.Uma kudingeka, ukulawulwa kwe-PLC kungenziwa ngomshini wokulahla, ngakho-ke kuyoba lula ukusetha isikhathi, isivinini, izinga lokushisa nezinye izici futhi umshini uzoba nenkumbulo.Ngeke ukhathazeke ngokushiya kwabasebenzi abadala, ngoba abasebenzi abasha bazokwenza umsebenzi nge-PLC.

IMIPHAKATHI YOBUCHWEPHESHE EYIZIGANEKO (EZENZAKALELAYO).

Amasampula e-Laminating:

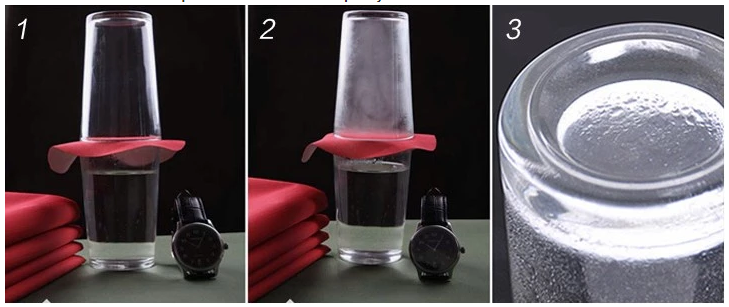

Izinto Ezinamalayithi Ezingenamanzi kanye Nokuhlolwa Kwekhono Eliphefumulayo

Isikhathi sokuthumela: Jan-06-2024