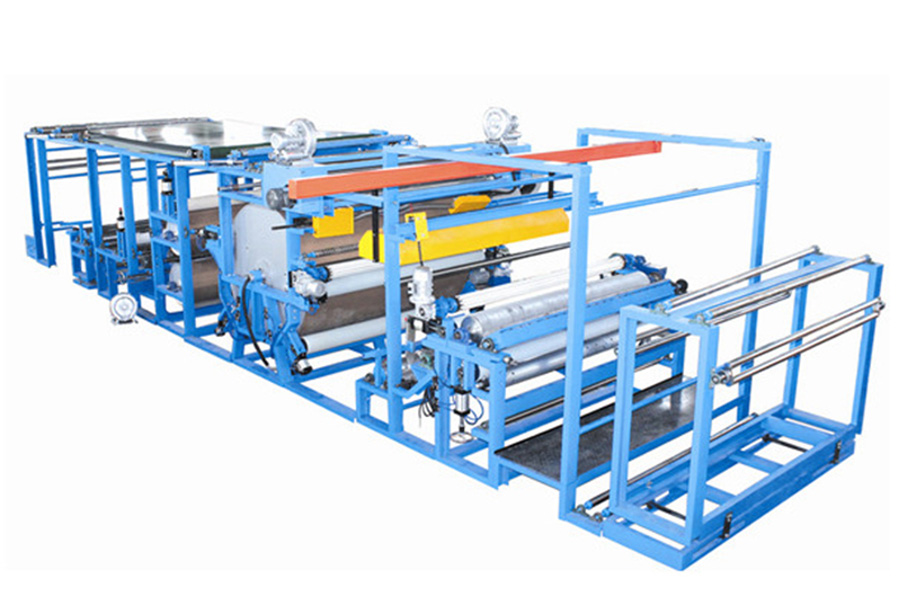

Umatshini wokuhlambas sisixhobo esikhulu sokwenza iqhina eliqinileyo phakathi kweentlobo ezimbini ezahlukeneyo zemathiriyeli.Ukuba ukushishino olulukiweyo, udinga umatshini ethembekileyo laminating ukonyusa imveliso yakho ukusebenza kakuhle.Ilaphu ukuya kumatshini wokuhlamba i-laminating lukhetho oludumileyo kuba lunokusingatha iintlobo ezahlukeneyo zeelaphu, amalaphu angalukwanga, amalaphu, angenamanzi, kunye neefilimu eziphefumlayo.

Nazi izinto ezintandathu ezenza ilaphu lomatshini wokuhlamba ilaphu kufuneka ubenawo kubavelisi belaphu:

1. Ukuguquguquka

Ilaphu ukuya kwilaphu umatshini laminating unamandla ancamathelayo elomeleleyo ezinokudibanisa izixhobo kunye ngokulula.Ilungele iintlobo ezahlukeneyo zemathiriyeli ezifana namalaphu, amalaphu angalukwanga, amalaphu, amalaphu angangeni manzi, kunye neefilimu eziphefumlayo.Ngalo matshini, unokwenza iimveliso ezilaminethiweyo ezomeleleyo, eziphefumlayo, ezihlambekayo, kunye nezomileyo ezicocekileyo.Ungayisebenzisa ukwenza iimveliso ezikwaziyo ukumelana namanzi kunye nolunye ulwelo.

2. ULawulo lweNkqubo yePLC

Ilaphu ukuya kumatshini wokuhlamba ilaphu usebenzisa inkqubo yokulawula ingqiqo (PLC) ekuvumela ukuba ulawule ngokulula ukusebenza kwayo.Unokuseta umatshini ukuba enze imisebenzi eyahlukeneyo efana nokulawula ubushushu, ukulawulwa kwesantya, kunye nohlengahlengiso loxinzelelo.I-man-machine touch interface yenza kube lula kuwe ukuba usebenzise umatshini.

3. Advanced Edge-Ukulungelelanisa kunye neSixhobo sokuBhala

Ilaphu ukuya kulaphuumatshini wokuhlambainesixhobo esiphucukileyo solungelelaniso somphetho kunye nokubhala esiphucula iqondo lokuzitshintsha.Olu phawu lugcina iindleko zabasebenzi, lunciphisa ukuxinana kwabasebenzi, kwaye luphucula impumelelo yemveliso.Umatshini unokulungelelanisa ngokuchanekileyo imiphetho yezinto ngaphambi kokuba zidibanise.Oku kuqinisekisa ukuba imveliso yokugqibela icocekile kwaye igqibelele.

4. Ukubambisana okuPhezulu

Ilaphu ukuya kumatshini wokulamba ngelaphu lisebenzisa nokuba yi-PU glue okanye iglu esekwe kwi-solvent ukuze idibanise izixhobo kunye.Imveliso ye-laminated inokubambelela kakuhle kunye nokuvakalelwa kwesandla esihle.Ekubeni iglue inamachaphaza ngexesha le-lamination, imveliso inokuphefumula.Oku kuthetha ukuba imveliso yakho yokugqibela iya kukhululeka ukuyinxiba kwaye kulula ukuyinyamekela.

5. Isixhobo sokupholisa esisebenzayo

Ilaphu ukuya kwilaphu umatshini laminating linenkqubo esebenzayo yokupholisa eyandisa isiphumo lamination.Isixhobo sokupholisa sinceda ukulawula ubushushu bomatshini, ukuthintela ukutshisa.Oku kuqinisekisa ukuba umatshini unokuhamba kakuhle ixesha elide ngaphandle kokuphuka.

6. Imela yokuthunga

Ilaphu ukuya kumatshini wokuhlamba ilaphu linemela yokuthunga esetyenziselwa ukusika imiphetho ekrwada yelaminate.Imela iqinisekisa ukuba imiphetho icocekile kwaye ilungile, inika imveliso yakho ukugqitywa kobugcisa.Eli nqaku likongela ixesha kunye nemali kuba akufuneki ugqibezele imiphetho ngesandla.

Ukuqukumbela

Ilaphu ukuya kulaphuumatshini wokuhlambalutyalo-mali olukhulu kubavelisi belaphu abafuna ukuphucula isantya sabo semveliso kunye nomgangatho.Ngokuguquguquka kwayo, iimpawu eziphambili, kunye nokudibanisa okukumgangatho ophezulu, unokwenza iimveliso ezilayitiweyo ezihlala ixesha elide, ezikhululekile, kwaye kulula ukuzinyamekela.Fumana ilaphu lakho kumatshini wokuhlamba ilaphu namhlanje kwaye uthathe imveliso yakho yelaphu uye kwinqanaba elilandelayo!

Ixesha lokuposa: Oct-20-2023