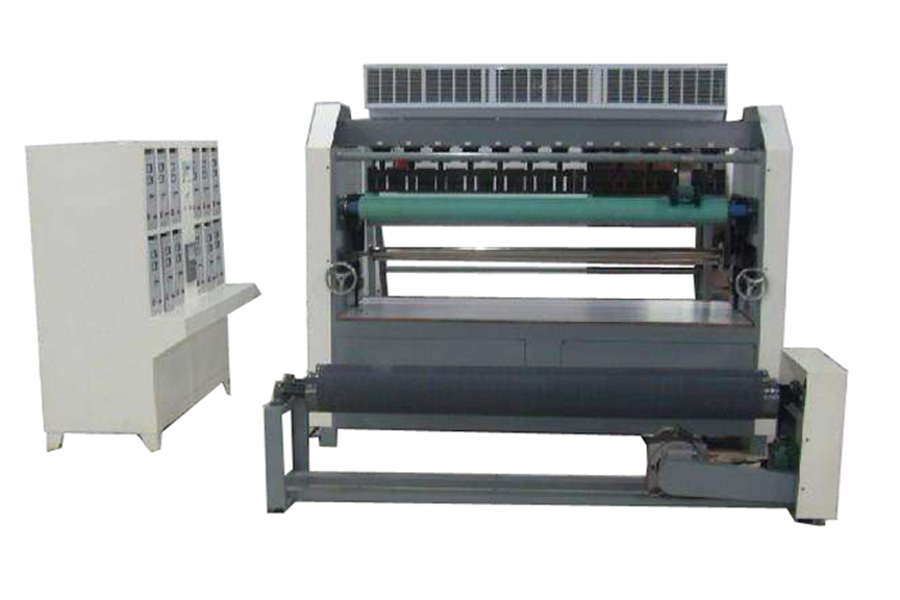

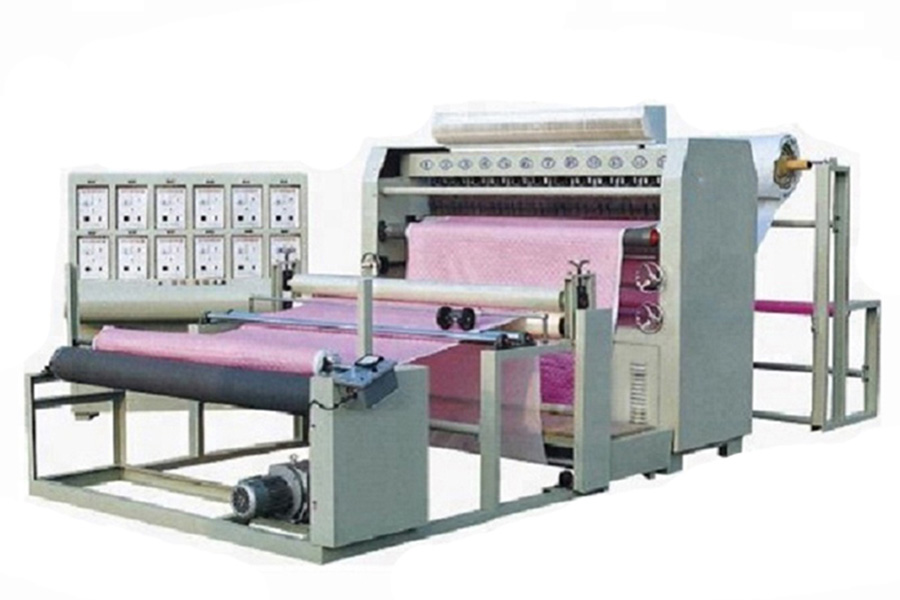

Ultrasonic Embossing Machine bakeng sa masela a sa lohiloeng

Mochini oa embossing oa Ultrasonic (mochini oa motsoako oa ultrasonic, mochini oa seaming oa ultrasonic, mochini oa ultrasonic quilting, ultrasonic tweezer) ke leqhubu la maqhubu a phahameng a thothomelang le fetisetsoang libakeng tse peli kapa ho feta hore li be le welded, tabeng ea khatello ea maikutlo. theha motsoako pakeng tsa likarolo tsa molek'hule, 'me e loketse bakeng sa tjheseletsa ea lesela le lesela, lesela le k'hothone ea fiber ea lik'hemik'hale, filimi ea polasetiki le filimi ea polasetiki.Haholo-holo e sebelisoa ka seile ea koloi, sekoaelo sa koloi, thōtō, mekotla ea matsoho, lieta, liaparo, liaparo tsa bana, sekoaelo sa mosamo, sekoaelo sa materase, mosamo oa mosamo, lesela la tafole la tafole, lesela la shaoara ea likharetene, liatlana tse batang, lesela la lesea le sa keneng mongobo, lisebelisoa tsa lapeng, liaparo, polokelo, liaparo tsa tente, sekoahelo sa mochini o hlatsoang, mokotla oa 'mè, mokotla o phodileng oa botlolo, kobo ea motlakase, mokotla oa litlolo, sekoahelo sa sutu, bethe ka tlas'a khabinete, sekoahelo sa sauna, mokotla oa lieta Polokelo ea lebokose la mokotla, letamo la PVC tlase, joalo-joalo.

Likaroloana

1. Nako ea ho tjheseletsa e khuts'oane, nale le khoele ea othomathike ea ultrasonic suture, e felisang tlhoko ea nale khafetsa bakeng sa khathatso, lebelo la ho roka ke makhetlo a 5 ho isa ho a 10 mochining oa ho roka o kentsoeng, ka bophara ke moreki.

2. Ka lebaka la ho se be le lisebelisoa, ho qoba mokhoa oa ho roka ka nale e robehileng ka thepa ka har'a boemo, ho felisa likotsi tsa ts'ireletso, moloko o mocha oa lihlahisoa tsa tšireletso le tikoloho;

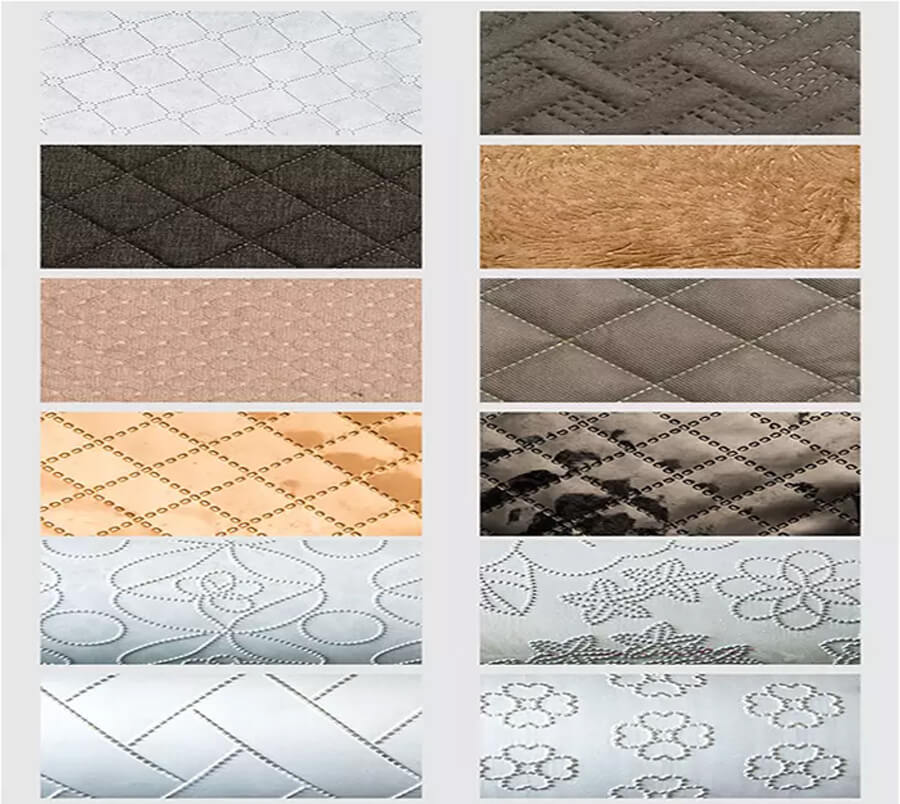

3. Ha ho na mela e tloaelehileng ea ho roka manonyeletso a ho khaola, ho khomarela ka matla, ho ngotsoe ka mokhoa o hlakileng, bokaholimo bo na le phello e ntle ea likarolo tse tharo, sehlahisoa se setle haholoanyane;

4. Ka mor'a ho sebetsana le lihlahisoa ntle le li-pinholes ha li bonepage, ho feta metsi le phello e futhumetseng;

5. Tšebeliso ea hlobo ea lipalesa ea lipalesa, hlobo e bonolo, e ka rokoa ho tsoa ho mekhoa e sa fetoheng le e rarahaneng e sa tsoeleng pele le e lekanang, empa hape ho ea ka litlhoko tsa bareki ho hlahisa mefuta e sa tšoaneng ea sebopeho sa lipalesa;

6. Ho ea ka litšobotsi tsa thepa ea bareki, e ka etsoa ka mokhoa o ikhethileng.

Mekhahlelo ea mantlha ea tekheniki

| Thepa Lebitso | Mochini oa ho Embossing oa Ultrasonic |

| Matla a jenereithara a acoustic | 600W * 12 / Customrized |

| Khafetsa | 20KHZ/E khethiloe |

| Matla | 380V, 50HZ/E khethiloe |

| Paterone-rolara bophara | φ136mm/E khethiloe |

| Lebelo | 10-30 m/min |

| Boemo | 8000×2500×1550mm |

| Boima ba 'mele | 3000 KG |

LBH

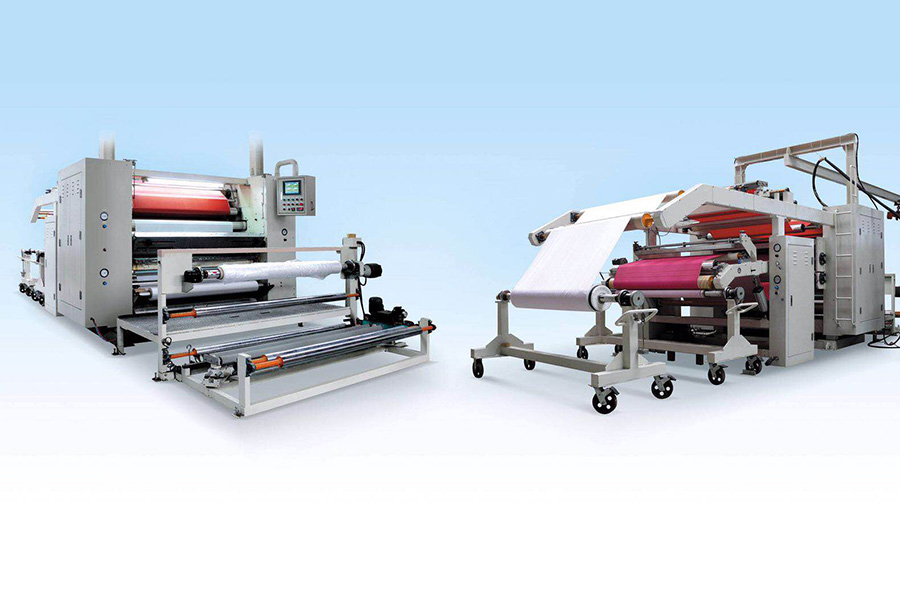

Mochini oa laminating ke eng?

Ka kakaretso, mochini oa laminating o bolela sesebelisoa sa lamination se sebelisoang haholo masela a lapeng, liaparo, thepa ea ka tlung, ka hare ho likoloi le liindasteri tse ling tse amanang le tsona.

E sebelisoa haholo bakeng sa ts'ebetso ea tlhahiso ea masela a mabeli kapa a mangata a masela a fapaneng, letlalo la tlhaho, letlalo la maiketsetso, filimi, pampiri, seponche, foam, PVC, EVA, filimi e tšesaane, joalo-joalo.

Haholo-holo, e arotsoe ka sekhomaretsi laminating le sa sekhomaretsi laminating, 'me sekgomaretsi laminating arotsoe ka metsi thehiloeng sekhomaretsi, PU oli sekgomaretsi, solvent-based sekhomaretsi, khatello ea kelello sekhomaretsi, super sekhomaretsi, chesang qhibiliha sekhomaretsi, joalo-joalo The non-sekgomaretsi mokhoa oa laminating boholo ba ka ho toba thermocompression bonding pakeng tsa thepa kapa lelakabe combustion lamination.

Mechini ea rona e etsa ts'ebetso ea Lamination feela.

Ke lisebelisoa life tse loketseng ho laminate?

1

(2) Lesela le nang le lifilimi, joalo ka filimi ea PU, filimi ea TPU, filimi ea PTFE, filimi ea BOPP, filimi ea OPP, filimi ea PE, filimi ea PVC ...

(3) Letlalo, letlalo la maiketsetso, Seponche, Foam, EVA, Plastiki....

Ke indasteri efe e hlokang ho sebelisa mochini oa laminating?

Mochini oa Laminating o sebelisoang haholo ho phethela masela, feshene, lieta, cap, mekotla le lisutuk'heise, liaparo, lieta le likatiba, mekotla, masela a lapeng, li-interiors tsa likoloi, mokhabiso, liphutheloana, li-abrasives, papatso, lisebelisoa tsa bongaka, lihlahisoa tsa bohloeki, thepa ea moaho, lintho tsa ho bapala. , masela a liindasteri, lisebelisoa tsa filthara tse se nang tikoloho joalo-joalo.

Joang ho khetha mochine o loketseng ka ho fetisisa oa laminating?

A. Ke lintlha life tse hlokahalang bakeng sa tharollo ea lintho tse bonahalang?

B. Ke litšobotsi life tsa thepa pele laminating?

C. Tšebeliso ea lihlahisoa tsa hau tsa laminated ke efe?

D. Ke lisebelisoa life tseo u lokelang ho li finyella ka mor'a lamination?

Nka kenya mochini le ho o sebelisa joang?

Re fana ka litaelo tse qaqileng tsa Senyesemane le livideo tsa ts'ebetso.Moenjiniere a ka boela a ea mose ho fektheri ea hau ho kenya mochine le ho koetlisa basebetsi ba hau hore ba sebetse.

Na ke tla bona mochini o sebetsa pele o reka?

Amohela metsoalle lefatšeng ka bophara ho etela feme ea rona nako efe kapa efe.