TLHOKOMELISO EA MACHINE EA LAMINATING:

1. E sebelisoa bakeng sa gluing le laminating ea lesela, nonwoven, textile, waterproof, breathable films joalo-joalo.

2. E thusoa ke taolo ea lenaneo la PLC le sebopeho sa mochine oa motho, ho bonolo ho sebetsa.

3. Lisebelisoa tse tsoetseng pele tsa ho hokahanya le lisebelisoa tsa scothing, mochine ona o eketsa tekanyo ea ho iketsetsa, o boloka litšenyehelo tsa basebetsi, o imolla matla a mosebetsi, 'me o ntlafatsa katleho ea tlhahiso.

4. Ka PU glue kapa solvent based glue, lihlahisoa tsa laminated li na le thepa e ntle ea sekhomaretsi 'me li ama hantle.Li ka hlatsuoa ebile lia hloeka.Ka lebaka la sekhomaretsi se ka mokhoa oa ntlha ha laminating, lihlahisoa tsa laminated li phefumoloha.

5. Sesebelisoa se pholileng se sebetsang hantle se ntlafatsa phello ea lamination.

6. Sekhahla sa ho roka se sebelisetsoa ho khaola likarolo tse tala tsa lisebelisoa tsa laminated.

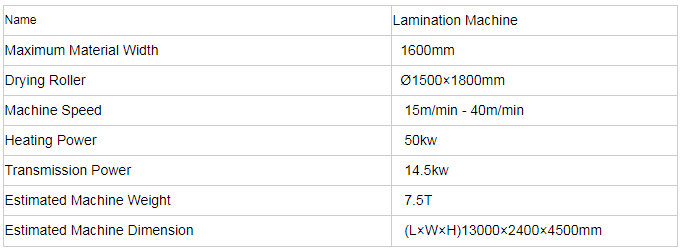

LITLHAKISO TSA LAMINATING:

1.Lesela + lesela: masela, jeresi, boea, Nylon, Velvet, Terry cloth, Suede, joalo-joalo.

2.Lesela + lifilimi, joalo ka filimi ea PU, filimi ea TPU, filimi ea PE, filimi ea PVC, filimi ea PTFE, joalo-joalo.

3.Lesela+ Letlalo/Letlalo la Maiketsetso, joalo-joalo.

4.Lesela + Nonwoven

5.Lesela la ho qoela

6.Seponche/ Foam with Fabric/ Letlalo la maiketsetso

7.Polasetiki

8.EVA+PVC

SEBELISA HAHOLO HO:

1.Indasteri ea Liaparo le Liaparo

2.Medical Products Industry

Indasteri ea 3.Bags le Luggage

4.Packaging Industry

5.Indasteri ea lieta

6.Indasteri ea Khabiso

7.Auto ka hare mokhabiso Industry

LITŠOANTŠISO TSA BOHLOKOA:

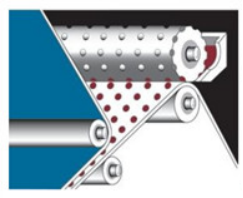

1.Solvent based glue kapa PU glue e sebetsa bakeng sa mochine oa laminating.

2.Sekhomaretsi se fetisetsoa ka mokhoa o ts'oanang holim'a lintho tse bonahalang ka rolara e betliloeng (letheba kapa sebopeho sa daemane kapa

dibopeho tse ding).Ka hona, lisebelisoa tsa laminated li bonolo, ha li na metsi ebile li phefumoloha.

3.Bongata ba sekhomaretsi bo khethoa ke lintlha tse peli: sebaka se pakeng tsa sekhomaretsi le sekhomaretsi

scraping blade (taolo ea pneumatic) 'me ea bobeli, sekhomaretsi rolara letlooeng u khetha bakeng sa mochine laminating.

4.Special mocheso phahameng manganga le antirust pampiri Teflon holim'a drying rolara e sireletsa

thepa 'matsoho pele le e ikhethang le litšobotsi le thibela sekhomaretsi ho tloha khomarela rolara ea mochine laminating.

5.Sesebelisoa se khethehileng sa ho phutholla filimi le mochini oa ho khutlisa lesela la lifilimi li kentsoe holim'a poleiti e kaholimo, ho thusa.

tshebetso mmoho le ho boloka sebaka.Sekhomaretsi se ka fetisetsoa filiming kapa lesela le leng pele ho laminating, likhetho tse ling.

6.Sesebelisoa se pholileng se sebetsang hantle se matlafatsa phello ea lamination.

LIKA KHETHA:

1.Both sesebediswa unwinding le matsoelintsoeke mochine laminating na le matla a khoheli kamehla taolo ya tsitsipano.

2.Automatic hydraulic centering device e tiisa hore ho tsamaisana le bohale ho laminating.

3.Pneumatic ho atolosa shaft e kenngoa bakeng sa ts'ebetso e bonolo ea mochine oa laminating.

4.Fabric Spreading Rollers kapa Openers

5.Tension Controller

6.Gear Transmission e tla sebelisoa ho pota-pota sesebelisoa sa gluing le ho omisa rolara le lebanta la synchrony le ka boela la sebelisoa ho nka sebaka sa phetiso ea ketane moo ho hlokahalang, ka hona ho tla ba le lerata le fokolang ha ho tsamaisoa mahcine ea laminating le lebelo le tla lumellana hantle.

7.Bakeng sa masela a otlollang a 4, ho tla kenngoa sete e feletseng ea lisebelisoa tse khethehileng.

Sesebelisoa sa 8.Automatic Edge Trimming se tla kenngoa.Haeba ho hlokahala, sesebelisoa sa ho tlosa litšila se ka eketsoa.

9.Haeba ho hlokahala, Siemens kapa Mitsubishi motors e ka sebelisoa.

10.Haeba ho hlokahala, taolo ea PLC e ka phethahala ka mochine oa laminating, kahoo ho tla ba bonolo ho beha nako, lebelo, mocheso le lintlha tse ling 'me mochine o tla ba le mohopolo.U ke ke ua tšoenyeha ka basebetsi ba baholo ba tlohang, hobane basebetsi ba bacha le bona ba tla etsa mosebetsi le PLC.

LIPARAMETENG TSA TECKNICAL E TLOAELEHANG (E TLOAELEHANG).

Mehlala ea Laminating:

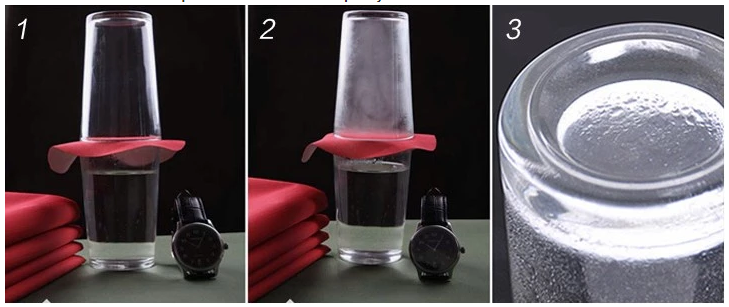

Lisebelisoa tsa Laminated tse sa keneleng Metsi le Teko ea Matla a Phefumolohang

Nako ea poso: Jan-06-2024