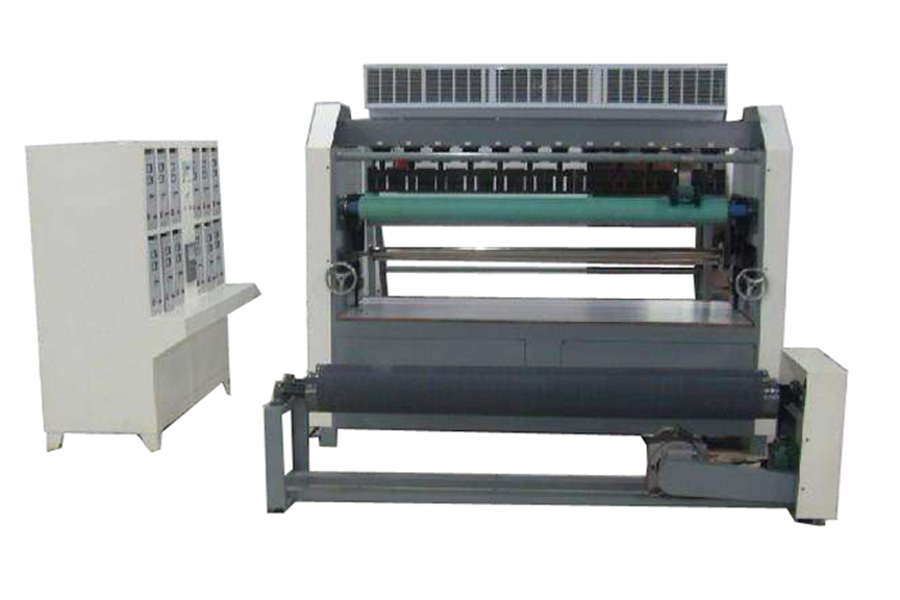

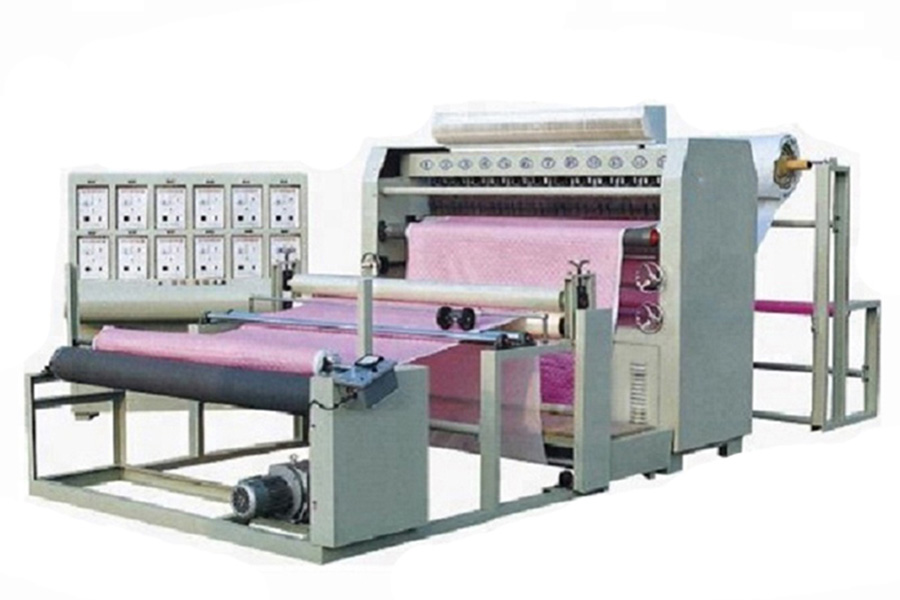

Ultrasonic Embossing Machine yemachira asina kurukwa

Ultrasonic embossing muchina (ultrasonic komputa muchina, ultrasonic seaming muchina, ultrasonic quilting muchina, ultrasonic tweezer) ndeye yakakwira-frequency vibration wave inotumirwa kune maviri kana anopfuura maficha kuti asungirwe, kana iri kudzvanywa. gadzira musanganiswa pakati pema molecular layers, uye inokodzera welding yejira nemucheka, machira nemakemikari fiber cotton, firimu repurasitiki uye firimu repurasitiki.Inonyanya kushandiswa mumotokari tarpaulin, chivharo chemotokari, mabhegi, mabhegi, shangu, zvipfeko, zvipfeko zvevana, chivharo chepillow, chivharo chemetiresi, cushion pillow, tafura mat tablecloth, curtain shower curtain, cold gloves, baby mat Moistureproof pad, kumba accessories, wadhiropu, chengetedzo, wadhiropu yetende, chivharo chemuchina wokuwachisa, bhegi remummy, bhodhoro rinotonhorera bhegi, gumbeze remagetsi, bhegi rekuzora, chivharo chesutu, mubhedha pasi pekabati, chivharo chesauna, bhegi reshangu Storage box bag, PVC dziva pasi, nezvimwe.

Features

1. Welding nguva ipfupi, otomatiki ultrasonic suture tsono uye shinda, kubvisa kudiwa kweanowanzo gadzira tsono yedambudziko, kasi yekusonesa ndeye 5 kusvika ka10 muchina wekusonesa wakavharwa, wakafara nemutengi wega-

2. Somugumisiro wekushaya tsono, kudzivisa nzira yekucheka nenyuchi yakaputsika muzvinhu mukati memamiriro ezvinhu, kubvisa njodzi dzekuchengetedza, chizvarwa chitsva chekuchengetedza uye zvigadzirwa zvekuchengetedza zvakatipoteredza;

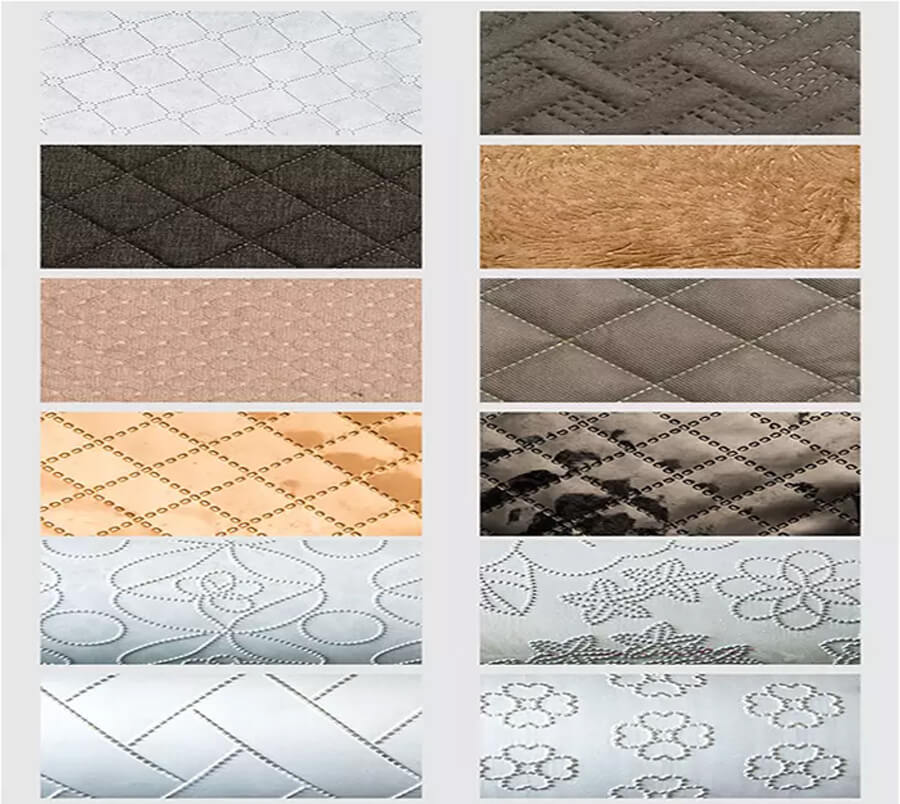

3. Hapana chinyakare mutsara kusona disconnection joints, yakasimba inonamira, embossed yakajeka, iyo yepamusoro inowedzera matatu-dimensional yekuyamura maitiro, chigadzirwa chakanyanya kunaka-kumagumo;

4. Mushure mekugadzirisa zvigadzirwa zvisina pinholes hazvione, zvakanyanya kusapinda uye kudziya kwekuita;

5. Kushandiswa kwemaruva roll mold, mold kuti zvive nyore, zvinogona kubatanidzwa kunze kwekugara-kushanduka uye kwakaoma kusingapfuuri uye maitiro ekuenzanisa, asiwo maererano nezvinodiwa nevatengi kukudziridza maitiro akasiyana-siyana emhando yemaruva;

6. Maererano nemutengi zvinhu maitiro, anogona kugadziriswa.

Main Technical Parameters

| Equipment Name | Ultrasonic Embossing Machine |

| Acoustic jenareta simba | 600W * 12 / Yakagadzirirwa |

| Frequency | 20KHZ/Customrized |

| Simba | 380V, 50HZ/Customrized |

| Pattern-roller dhayamita | φ136mm/Customrized |

| Speed | 10-30 m/min |

| Dimension | 8000×2500×1550mm |

| Kurema | 3000 KG |

FAQ

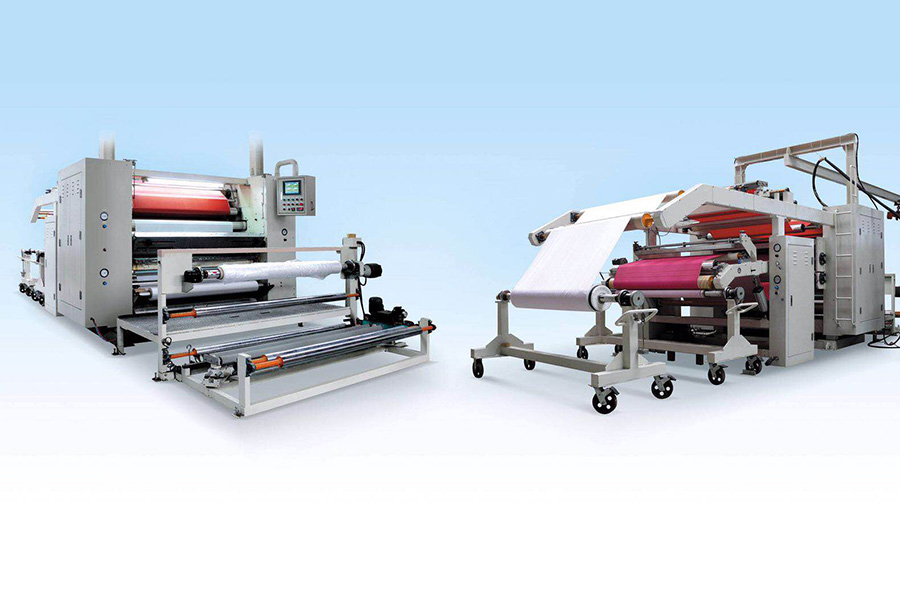

Chii chinonzi laminating machine?

Kazhinji kutaura, muchina wekuchemedza unoreva mudziyo welamination uyo unoshandiswa zvakanyanya mumachira epamba, zvipfeko, fenicha, zvemukati zvemotokari uye mamwe maindasitiri ane hukama.

Inonyanya kushandiswa kune maviri-layer kana akawanda-layer bonding maitiro ekugadzira akasiyana machira, echisikigo dehwe, artifical dehwe, firimu, bepa, chipanje, furo, PVC, EVA, nhete firimu, nezvimwewo.

Kunyanya, iyo yakakamurwa kuita adhesive laminating uye isina-adhesive laminating, uye adhesive laminating yakakamurwa kuva mvura based glue, PU mafuta adhesive, solvent-based glue, pressure sensitive glue, super glue, hot melt glue, etc. Iyo isina-adhesive laminating process inonyanya kunanga thermocompression bonding pakati pezvinhu kana flame combustion lamination.

Michina yedu inongogadzira Lamination process.

Ndezvipi zvinhu zvakakodzera laminating?

(1) Mucheka une jira: machira akarukwa uye akarukwa, asina kuruka, jezi, mvere, Nylon, Oxford, Denim, Velvet, plush, suede jira, interlinings, polyester taffeta, nezvimwewo.

(2) Micheka ine mafirimu, sePU firimu, TPU firimu, PTFE firimu, BOPP firimu, OPP firimu, PE firimu, PVC firimu...

(3) Leather, Synthetic dehwe, Sponge, Foam, EVA, Plastic....

Ndeipi indasitiri inoda kushandisa laminating muchina?

Laminating muchina unoshandiswa zvakanyanya mukupedzisa machira, fashoni, shangu, cap, mabhegi uye masutukesi, zvipfeko, shangu neheti, mikwende, machira epamba, zvemukati zvemotokari, kushongedza, kurongedza, abrasives, kushambadzira, zvekurapa, zvigadzirwa zvehutsanana, zvekuvakisa, matoyi. , machira emaindasitiri, zvakatipoteredza zvine hushamwari sefa zvinhu nezvimwe.

Nzira yekusarudza sei yakakodzera laminating muchina?

A. Chii chinodiwa chekugadzirisa zvinhu?

B. Ndeapi maitiro ezvinyorwa asati laminating?

C. Ndeipi kushandiswa kwezvigadzirwa zvako zvelaminated?

D. Ndezvipi zvinhu zvenyama zvaunoda kuti uwane mushure mekucheka?

Ndingaite sei kuisa nekushandisa muchina?

Isu tinopa yakadzama yekuraira kweChirungu uye mavhidhiyo ekushanda.Injiniya inogona zvakare kuenda kunze kwenyika kufekitori yako kuisa muchina uye kudzidzisa vashandi vako kushanda.

Ndoona muchina uchishanda usati warongeka?

Gamuchira shamwari pasi rese kuti shanyira fekitori yedu chero nguva.