Shoe kugadzira zvinhu laminating muchina

Iyo shangu yekugadzira zvinhu inonyanya kuumbwa nezvikamu zvishanu zvinotevera

1.Leather.

Dehwe rinochinjika asi rakasimba, sekusimba kwaro.Iyo elastic, saka inogona kutambanudzwa asi inoramba kubvaruka uye kubvongodzwa.

2.Micheka.

Mucheka unonyanya kushandiswa kugadzira shangu.Kufanana nematehwe, machira anowanikwa mumhando dzakasiyana dzemavara nemhando.

3.Synthetics.

Zvishandiso zvekugadzira zvinoenda nemazita mazhinji akasiyana- PU dehwe kana kungoti PU, dehwe rekugadzira kana kungoita zvekugadzira- asi zvese zvakafanana mukuva maumbirwo akagadzirwa nevanhu maviri.

4.Rubber.

Rubber inonyanya kushandiswa mushangu kugadzira soles.

5.Foam.

Foam ndiyo inonyanya kushandiswa kutsigira kumusoro kweshangu dzemarudzi ese, angave matehwe, machira, ekugadzira kana kunyange rabha.

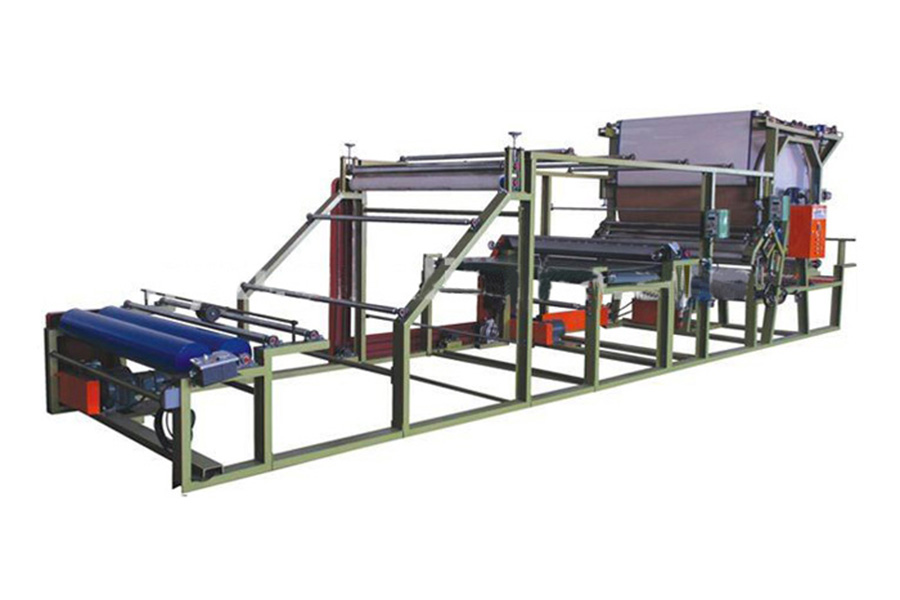

Laminating Machine Features

1.Inoshandisa glue-based glue.

2.Kuvandudza hutano hwezvigadzirwa zvakanyanya, chengetedza mari.

3. Vertical or horizontal structure, low breakdown rate and long service time.

4. The material feeding roller inotungamirirwa nemhepo cylinder, ichiziva zvakanyanya kukurumidza, zviri nyore uye zvakajeka maitiro.

5. Yakashongedzerwa nehupamhi hwekupisa kupisa kwebhandi remambure kuita kuti laminated zvinhu zvibatane zvakanyanya neaomesa humburumbira, kuvandudza kuomeswa uye kusungirirwa kwekuita, uye kuita kuti laminated chigadzirwa chive chinyoro, chinowachika, uye chisimbise kusimba kwekunamatira.

6. Pane glue scraping blade yekukwenya glue zvakaenzana pamucheka uye iyo yakasarudzika glue chiteshi dhizaini inofambisa kucheneswa kweglue mushure mekutsvaira.

7. Iyi laminating muchina ine maviri seti yekudziya system, mushandisi anogona kusarudza imwe seti yekudziya modhi kana maviri seti, kuderedza kushandiswa kwesimba uye kuderedza mari.

8. Surface yekudziya roller yakaputirwa neTeflon kuitira kuti ishande kudzivirira iyo inopisa yakanyunguduka yakanamatira inonamatira pamusoro peiyo roller uye carbonization.

9. For clamp roller, zvose kugadzirisa vhiri remaoko uye pneumatic control inowanikwa.

10. Otomatiki infrared centering control unit inonyatso kudzivirira kutsauka kwebhandi remambure uye inorebesa hupenyu hwesevhisi yebhandi.

11. Yese mapaipi ekupisa mumucheka wekuomeswa anogadzirwa nesimbi isina tsvina uye tembiricha yekudziya yekuomesa roller inogona kusvika 160 celcius degree, uye kunyange 200 celcius degree.Iko kunowanzo kune maviri seti yekudziya system mune yekuomesa roller.Iyo yekudziya inongochinja kubva kune imwe seti kuenda kumaseti maviri.Yakachengeteka uye inochengetedza simba.

12. Kuverenga mudziyo uye rewinding mudziyo yakaiswa pamushini.

Zviri nyore kuchengetedza muchina uye mari yekugadzirisa yakaderera.

13. Yakashongedzerwa ne otomatiki infrared centering control unit, iyo inogona kunyatso kudzivirira kutsauka kwebhandi remambure, uye kuve nechokwadi chehupenyu hwebasa remambure.

14. Customized kugadzira inowanikwa.

15. Mari yekuchengetedza yakaderera uye iri nyore kuchengetedza.

Main Technical Parameters

| Kupisa nzira | Kudziya kwemagetsi/Kudziya kwemafuta/Steam kudziyisa |

| Diameter (Muchina Roller) | 1200/1500/1800/2000mm |

| Kushanda Speed | 5-45m/min |

| Kupisa Simba | 40kw |

| Voltage | 380V/50HZ, 3 chikamu |

| Kuyera | 7300mm * 2450mm2650mm |

| Kurema | 3800kg |

FAQ

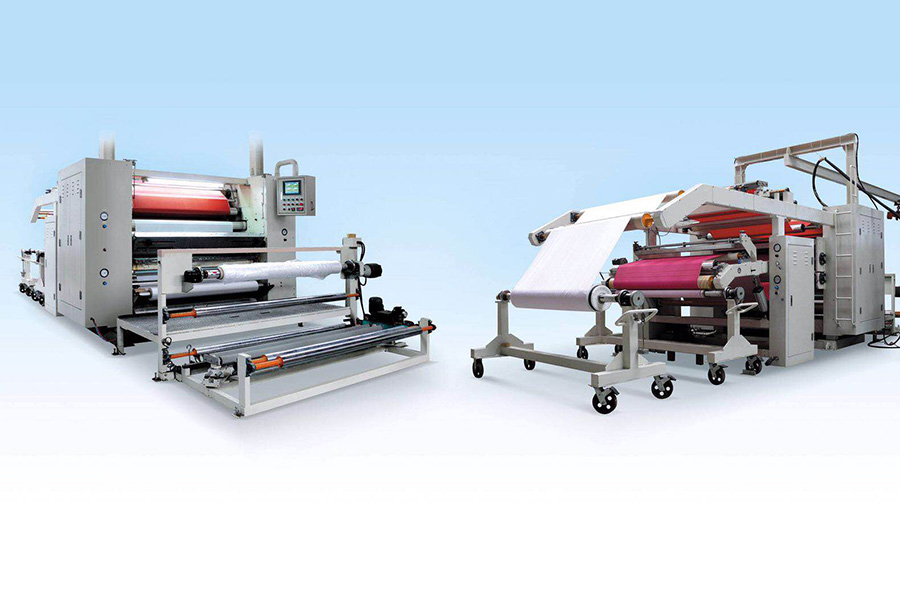

Chii chinonzi laminating machine?

Kazhinji kutaura, muchina wekuchemedza unoreva mudziyo welamination uyo unoshandiswa zvakanyanya mumachira epamba, zvipfeko, fenicha, zvemukati zvemotokari uye mamwe maindasitiri ane hukama.

Inonyanya kushandiswa kune maviri-layer kana akawanda-layer bonding maitiro ekugadzira akasiyana machira, echisikigo dehwe, artifical dehwe, firimu, bepa, chipanje, furo, PVC, EVA, nhete firimu, nezvimwewo.

Kunyanya, iyo yakakamurwa kuita adhesive laminating uye isina-adhesive laminating, uye adhesive laminating yakakamurwa kuva mvura based glue, PU mafuta adhesive, solvent-based glue, pressure sensitive glue, super glue, hot melt glue, etc. Iyo isina-adhesive laminating process inonyanya kunanga thermocompression bonding pakati pezvinhu kana flame combustion lamination.

Michina yedu inongogadzira Lamination process.

Ndezvipi zvinhu zvakakodzera laminating?

(1) Mucheka une jira: machira akarukwa uye akarukwa, asina kuruka, jezi, mvere, Nylon, Oxford, Denim, Velvet, plush, suede jira, interlinings, polyester taffeta, nezvimwewo.

(2) Micheka ine mafirimu, sePU firimu, TPU firimu, PTFE firimu, BOPP firimu, OPP firimu, PE firimu, PVC firimu...

(3) Leather, Synthetic dehwe, Sponge, Foam, EVA, Plastic....

Ndeipi indasitiri inoda kushandisa laminating muchina?

Laminating muchina unoshandiswa zvakanyanya mukupedzisa machira, fashoni, shangu, cap, mabhegi uye masutukesi, zvipfeko, shangu neheti, mikwende, machira epamba, zvemukati zvemotokari, kushongedza, kurongedza, abrasives, kushambadzira, zvekurapa, zvigadzirwa zvehutsanana, zvekuvakisa, matoyi. , machira emaindasitiri, zvakatipoteredza zvine hushamwari sefa zvinhu nezvimwe.

Nzira yekusarudza sei yakakodzera laminating muchina?

A. Chii chinodiwa chekugadzirisa zvinhu?

B. Ndeapi maitiro ezvinyorwa asati laminating?

C. Ndeipi kushandiswa kwezvigadzirwa zvako zvelaminated?

D. Ndezvipi zvinhu zvenyama zvaunoda kuti uwane mushure mekucheka?

Ndingaite sei kuisa nekushandisa muchina?

Isu tinopa yakadzama yekuraira kweChirungu uye mavhidhiyo ekushanda.Injiniya inogona zvakare kuenda kunze kwenyika kufekitori yako kuisa muchina uye kudzidzisa vashandi vako kushanda.

Ndoona muchina uchishanda usati warongeka?

Gamuchira shamwari pasi rese kuti shanyira fekitori yedu chero nguva.