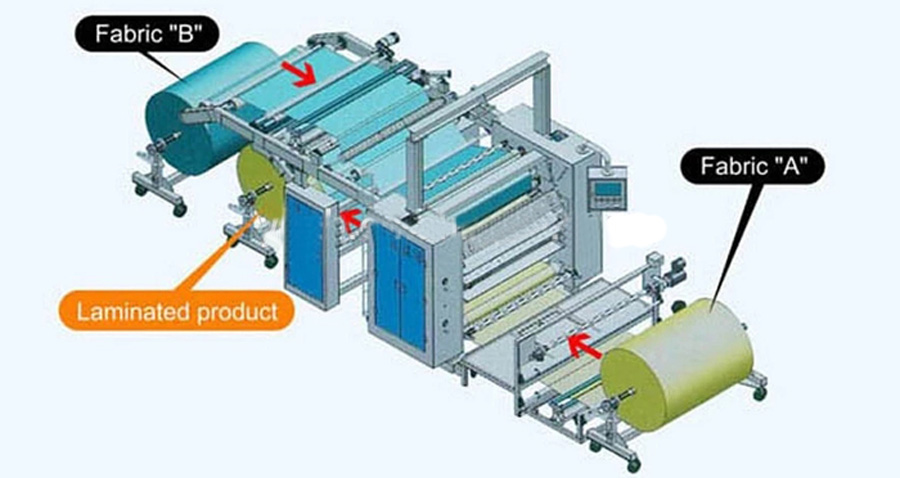

PUR Hot Melt Laminating Machine

Mukushandiswa kwemaindasitiri, zvinonamira zvinonyungudika zvinopisa zvinopa zvakati wandei zvakanakira pamusoro pezvinonamira zvinonyungudutsa.Volatile organic compounds inoderedzwa kana kubviswa, uye kuomesa kana kurapa nhanho inobviswa.Anonamatira anonyunguduka anopisa ane hupenyu hurefu hwesherufu uye kazhinji anogona kuraswa pasina matanho ekudzivirira.

Iyo yakanyanya kunyungudika inopisa inonamira, hunyoro reactive hot melt glue (PUR), inonamira zvakanyanya uye ine hushamwari.Inogona kushandiswa kugadzira 99.9% machira.Iyo laminated material yakapfava uye yakakwirira tembiricha inodzivirira.Mushure mekuita kwehunyoro, zvinhu hazvizove nyore kukanganiswa nekupisa.Kunze kwezvo, nekusingaperi elasticity, iyo laminated zvinhu haipfeki, inopesana nemafuta uye inodzivirira kuchembera.Kunyanya, kuita mhute, ruvara rwakarerekera uye zvimwe zvakasiyana zvePUR zvinoita kuti indasitiri yekurapa ishandiswe.

Mushure memakore ebudiriro nekusimudzira, kuita kweXinlilong Technology PUR Hot-Melt Laminating Machines kwakanakisa uye kunopfupikiswa mune zvinotevera:

1.Production kuyerera iri nyore.

2.Mechanical kufamba kwakarurama.

3.Mechanism uye Kudzora kweMagetsi zvakabatanidzwa mu cabinet, panel control iri nyore, kuchengetedza vanhu uye nguva mari.

4.Micro-Tension Control kugona kunogona kuwedzera marudzi ejira rejira, rinogona kugadziriswa (Coating & Laminating).

5.Kutora jira rejira zvakananga, uye kuita kushanda kune yakakwirira-kushanduka.

6.Kushandura jira rejira nokukurumidza, uye kuderedza nguva yekutungamirira yekushanda.

7.Modular design, michina iri nyore uye kugadzirisa iri nyore.

8.Kugadzikana kwakanyanya uye kuvimbika, mutengo wakaderera wekugadzira.

LAMINATING MATERIALS

1. Mucheka + jira: machira, jezi, mvere, Nylon, Velvet, Terry jira, Suede, nezvimwewo.

2. Micheka + mafirimu, akadai sePU firimu, TPU firimu, PE firimu, PVC firimu, PTFE firimu, nezvimwewo.

3. Mucheka + Leather / Artificial Leather, nezvimwewo.

4. Mucheka + Nonwoven

5. Diving Fabric

6. Sponge/ Foam neFabric/ Artificial Leather

7. Mapurasitiki

8. EVA+PVC

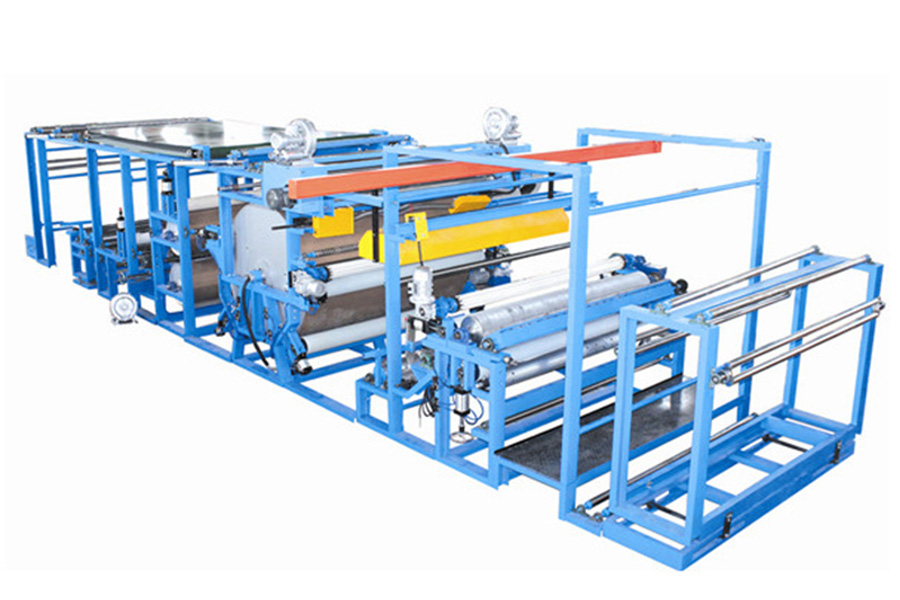

Main Technical Parameters

| Aihwa. | Zvikamu Zvikuru | DetailTsanangudzos |

| 1 | Main technical parameters | 1) Roller yakafara ndeye 1800mm, einoshandalaminating widthiri 1650mm. 2) Kunyanya kune laminating machira ne machira,isina-kurukwazvinhu, firimu, uye zvimwe zvinyoro zvinyoro nezvimwe. 3) Gluing nzira: glue kutamisaed ne gluing roller. 4) Kupisa nzira: Kupisa conduction mafuta choto. 5)Gluingroller: nhamba yemesh inoenderana nezvinodiwa nevatengi. 6) Basaing speed:0-35m/min. 7) Simba rekupa: 380V, 50HZ,3 phase. 8) Osimba rekudziya: 12-24KW inogadziriswa. Maximum tembiricha yekutenderera kwemafutais 180 °C. 9) Total midziyo simba:80KW. 10)Machine Size(L × W × H): 10200 ×2800 × 3200 mm. |

| 2 | Kudyisa&mudziyo wekusunungura | 1) Kudyisa&rolling trolley group: A-mota, yakazara3 seti. 2) AMaterial kudyamudziyo: humburumbira-mavhiriside toboka redivi (rine PID yekuona yekudzora mhando yemagetsi ziso),2pcsφ88 plating gidhi vhiri. 3) Tafura yekushanda: inoshanda tsoka pedal uye firimu inotenderedza torque mota michina boka uye3pcsφ88 electroplating gwaidhi vhiri. 4) Kudyisa firimu: firimudeliverfuremu uye kubata φ160 rubber vhiri * 1HP variable frequency drive uye1pcfirimu rekufambisa shaft. 5) Boka rekudzora tension risati rakura: φ75 aluminium vhiri maviri-mavhiri ekutamba ekutamba boka, akashongedzerwa nechaiyo pneumatic pombi yechikamu boka. 6) BMaterial kudyamudziyo: φ160 rubber transmission vhiri * 2HP siyana frequency drivekavirivhiri humburumbira rakatarisana neboka redivi, 3 pcsφ88 plating gidhi vhiri. 7) Bvisa vhiri risingavhurike usati wanamatira: φ125 tambo inovhurika vhiri. 8) Kuvhura vhiri pamberilaminating: Chinhu chinoiswa kune yekumberi tambo inovhurika vhiri uye 0.5HP frequency yekushandura dhiraivha uye B zvinhu zvinoiswa kune yekumberi aluminium pepa rinovhurika vhiri. |

| 3 | Mold tembiricha muchina | 1) Mold tembiricha muchina: chaiyo komputa inogadziriswa tembiricha yemafuta 0-180 ° C,simba rose r ndiro18kw. |

| 4 |

Glue meltmuchina

| 1) Nokutimeltglue: imwe seti ye200KGgluemelt muchinapamwe55 maritapressure plateuye gluechubhu (anti-scalding), LCD kuratidza,nyore kumove. |

| 5 | Gluing mudziyo | 1) Gluing unit:φ250 Gluingmuenzanisovhiri,2HP frequency kutendeuka,huru yekumhanyisa dhiraivha cheni giya uye inotenderera yakabatana uye inotakura uye hoko banga remhando yekuisa ndiro uye pneumatic kusimudza michina boka uyeφ250 kumashure kudzvanywa vhiri, nemagetsi ruoko kugadzirisa gap kuratidza Kudzora boka.Tatupcs gluingroller (ndokumbira simbisamuenzanisokufanoita). 2) Gluing roller shandukocrane: Single-track 500KG single-action inosimudza crane boka reiyo gluingkuchinjwa kwevhiri. |

| 6 | Laminatingmudziyo | 1) Laminatingchikwata: laminated electroplating rimφ250 * 2HP siyana frequency drive uyeφ250 rubber back pressure vhiri uyeφ250 press-fit mirror roller uye pneumatic lifting mechanism group, ine magetsi ekugadzirisa ruoko gap kuratidza control. 2) Kutonhora seti:φ250 electroplating kutonhora vhiri * 2 setipamwemajoini nemabhengi. |

| 7 | Mhepo mudziyo | 1) Boka rekudyisa: peya yematsutso inotsemuka. 2) Boka rekunetsana risati rapeta:φ100 aluminium vhiri tension group, ine chaiyo pneumatic pombi yechikamu boka, aluminium pepa rinovhurika vhiri risati rapetwa. 3) Boka rinotenderedza pasi:φ160 rubber transmission vhiri * 2HP inosiyana frequency drive uye pneumatic lifting mechanism group uye aluminium sheet risingatenderere vhiri risati ravhurika (hapana kutapurirana) uye spiral ruoko kumashure kumanikidza chaiko pneumatic piping chikamu boka,φ88 plating gwarowchitsitsinho *2pcs. |

| 8 | Electronic control system | 1) Munhu-muchina interface kubata sikirini kushanda, PLC kutonga. 2) PLC controller uye control moduleis nokutimTaiwan Yonghong. 3) Bata control screenmutauromuchirungu&ChiChinese. 4) Kudzora maitiro: Muchina wese unoshandiswa synchronously uye nechepakati inodzorwa neinverter.Iko kushanda kuri nyore uye kwakanakira, uye kuita kwakavimbika. 5) Motor reducer brand: Siemens. 6) Limit chinjamhando:CHINT. 7) Pneumatic componentsbrand: Taiwan Yadeke. 8) Digital tembiricha kudzora mitabrand: AOYI. 9) Vector Inverterbrand: Huichuan. 10) Kudzora kwehurongwa: all ma paramita akaiswa uye ane simba anoratidzwa pane yekubata skrini. 11) Kana muchina wese wabatidzwa, ese ekutyaira anotenderera otomatikikubatwa, inoparadzaniswa otomatiki kana muchina wamiswa, uyewoine basa rekuvhura nekuvhara kwemanyorero. 12) Iyo huru yepakati control cabinet iri pakati pemuchina, ine chiratidziro chekushanda uye mabhatani pamhepo. 13) Kudzora tambo: anti-kupindira tambo, yekubatanidza ine label, tambo bhokisi, yakarongedzwa zvakanaka kuti igadziriswe nyore.. |

| 9 | Mechanical parts&rack | 1) Simbi ndiro: GB-45. 2) Mbiri: GB chiteshi simbi, GB square chubhusimbi. 3) Column: 120 * 120 * 6 square chubhu,stafura uye anti-seismic. 4) Beam: 120 * 120 * 6 square chubhu,stafura uye anti-seismic. 5) Chimiro: Muchina wese unotora furemu chimiro uye unobviswa uye kutakurwa. 6) Mutungamiri roller: aluminium alloy,by anti-oxidation treatment, anti-scratch and scratch treatment, HV700 anode treatment, balance treatment, unbalance amount isingasviki 2g. |

| 10 | Machinekupenda | 1) Putty 2) Anti-ngura primer 3) Muvara wepende yepamusoro: beige (kana ruvara rwakasarudzwa nemutengi). |

Kushandisa Uye Zvimiro zveHot Melt Laminating Machine

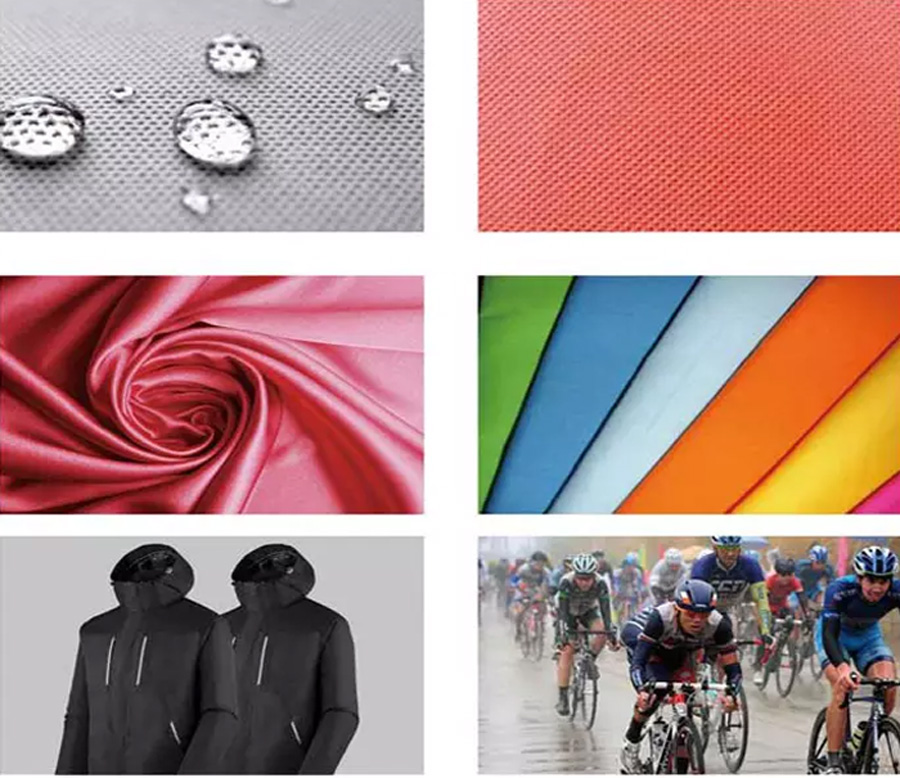

1. Yakaiswa kunama uye yekunamira yeglue inopisa yakanyunguduka pamicheka nezvinhu zvisina kuruka.

2. Anonamira anonyunguduka anopisa anoita kuti zvigoneke zvigadzirwa zvine hushamwari kwezvakatipoteredza uye haazive kusvibiswa panguva yese yekuita lamination.

3. Ndeyakanaka yekunamira pfuma, kuchinjika, thermostability, isiri-kutsemuka pfuma pakudziya kwakaderera.

4. Inodzorwa neProgrammable Logic Controller system ine touch screen uye modular yakagadzirwa chimiro, muchina uyu unogona kuve nyore uye nyore kushanda.

5. Famous brand motors uye inverters inogona kuiswa kuitira kugadzikana kwemashini kushanda

6. Non-tension unwinding unit inoita kuti laminated zvinhu zvipfave uye zvipfave, zvichivimbisa kunaka kwekubatana.

7. Micheka uye firimu inovhura inoitawo kuti zvinhu zvidye zvakanaka uye zvakadzikama.

8. Kune 4-nzira yakatambanudzwa machira, yakakosha machira ekufambisa bhandi anogona kuiswa pamushini welaminating.

9. Kusapinda kwekushisa mushure mePUR, elasticity inogara, kupfeka-resistance, mafuta kuramba uye anti oxidation.

10. Mutengo wekugadzirisa wakaderera uye ruzha rushoma.

11. Kana ichinge yaiswa mulamination yekushanda kwemvura isingapindi mwando inopindika mafirimu akadai sePTFE, PE neTPU, zvimwe zvinhu zvinodzivirira mvura uye zvinovharirwa, zvisingapindi mvura uye zvinodzivirira uye kusefa kwemafuta-mvura zvichatogadzirwa.

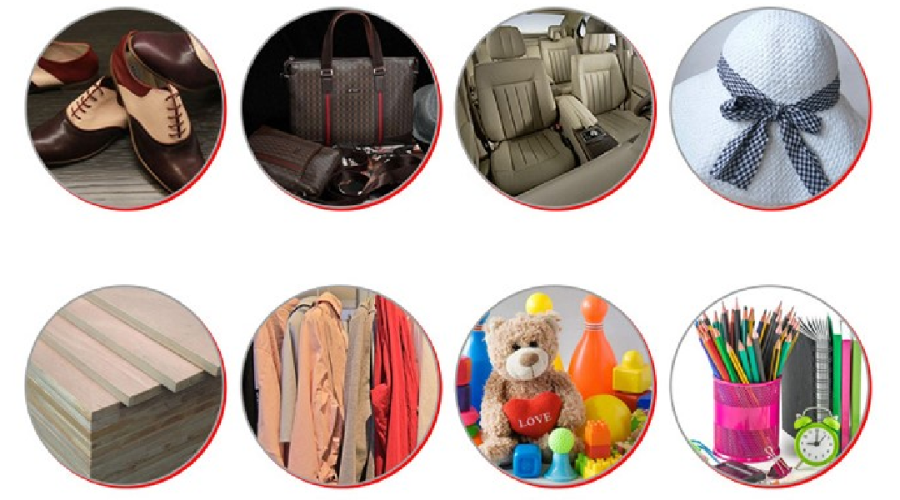

Inoshandiswa Zvakawanda In

Inoshandiswa zvakanyanya mumafekitori, indasitiri, zvivakwa, kuvaka, matura, nhandare dzendege, magasi uye dzimwe nzvimbo.isu tinokwanisa kugadzirisa zvakanyanya kufanirwa zvigadzirwa zvevashandisi zvinoenderana nezvinodiwa nemaindasitiri akasiyana.

FAQ

Uri fekitari here?

Ehe.Isu tiri nyanzvi mugadziri wemakina anopfuura makore makumi maviri.

Ko kunaka kwako?

Isu tinopa yakanakisa mhando uye mutengo unonzwisisika wemichina yese ine Perfect performance, Yakagadzikana kushanda, Professional dhizaini uye Hupenyu hurefu hwekushandisa.

Ndinogona here kugadzirisa muchina zvinoenderana nezvatinoda?

Ehe.OEM sevhisi ine yako logo kana zvigadzirwa zviripo.

Makore mangani iwe uchiendesa kunze muchina?

Takatumira michina kubva 2006, uye vatengi vedu vakuru vari muEgypt, Turkey, Mexico, Argentina, Australia, USA, India, Poland, Malaysia, Bangladesh etc.

Ndeipi yako mushure mekutengesa sevhisi?

Maawa makumi maviri nemana kutenderera wachi, 12 mwedzi waranti & kwehupenyu hwekuchengetedza.

Ndingaite sei kuisa nekushandisa muchina?

Isu tinopa yakadzama yekuraira kweChirungu uye mavhidhiyo ekushanda.Injiniya inogona zvakare kuenda kunze kwenyika kufekitori yako kuisa muchina uye kudzidzisa vashandi vako kushanda.

Ndoona muchina uchishanda usati warongeka?

Kugamuchirwa kushanyira fekitari yedu chero nguva.