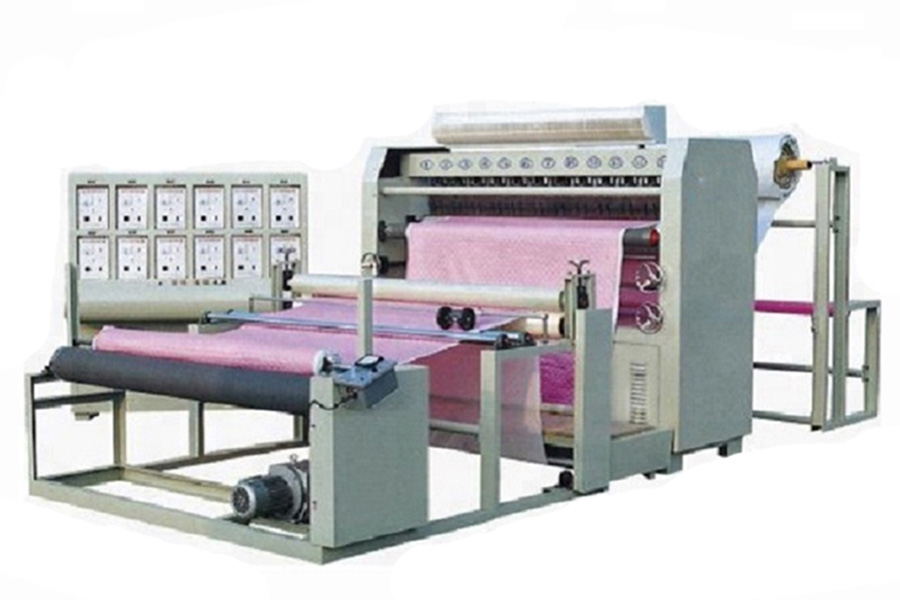

Ultrasonic embossing machines have emerged as a game changer in the textile industry, particularly in the field of non woven fabrics. These machines utilize high-frequency vibration waves to weld and bond two or more surfaces together, revolutionizing the way fabrics are embossed. With their advanced technology and capabilities, ultrasonic embossing machines offer six significant advantages for non woven fabrics.

1. Enhanced Durability: The ultrasonic embossing machine ensures a firm bond between fabrics, resulting in improved durability. The ultrasonic vibrations create a strong molecular bond between the surfaces, making the embossed patterns withstand rigorous usage and washing without losing their aesthetic appeal.

2. Time and Cost Efficiency: With ultrasonic embossing machines, the embossing process is significantly faster compared to traditional methods. The high-frequency vibration waves ensure quick and efficient bonding, enabling manufacturers to increase their production speed. Additionally, the automated process eliminates the need for additional labor, further reducing costs.

3. Versatile Design Options: Ultrasonic embossing machines offer a wide range of design options for non woven fabrics. These machines can create intricate and precise embossed patterns, allowing manufacturers to meet the diverse demands of the market. Whether it's floral, geometric, or abstract designs, the ultrasonic embossing machine can bring any pattern to life.

4. Environmentally Friendly: Ultrasonic embossing machines are environmentally friendly as they eliminate the need for adhesives or solvents in the embossing process. Traditional methods often rely on chemicals that can have harmful effects on the environment. By using ultrasonic vibrations, manufacturers can reduce their carbon footprint and contribute to a greener future.

5. Seamless Integration: The ultrasonic embossing machine can seamlessly integrate with other manufacturing processes. Whether it's ultrasonic cutting, folding, or quilting, these machines can be combined to create a complete production line. This integration ensures efficient workflow and reduces the chances of errors, improving overall productivity.

6. Enhanced Product Quality: The precision and accuracy of ultrasonic embossing machines result in superior product quality. The embossed patterns have clean and defined edges, giving the fabrics a premium look and feel. Additionally, the machines can maintain consistency across multiple batches, ensuring uniformity in the final products.

Ultrasonic embossing machines offer a wide range of applications. They are extensively used in various industries, including automotive, medical, packaging, and home textiles. From car interiors to medical gowns, these machines provide the perfect solution for adding aesthetic value and functionality to non woven fabrics.

In summary, ultrasonic embossing machines have revolutionized the embossing process for non woven fabrics. Their six significant advantages, including enhanced durability, time and cost efficiency, versatile design options, environmental friendliness, seamless integration, and enhanced product quality, have made them the go-to solution for manufacturers worldwide. With their advanced technology, these machines have undoubtedly raised the bar for fabric embossing, providing countless possibilities for innovative and high-quality products.

Post time: Jun-28-2023