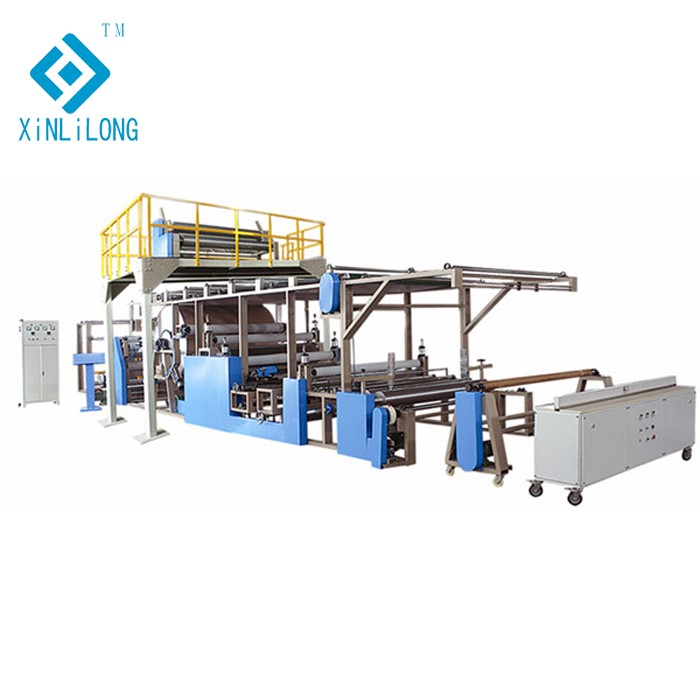

PU glue laminating machine refers to home textiles, clothing and other related industries in the composite equipment, used for all kinds of fabric, leather, film, paper, sponge and other two or more layers of lamination production process, specifically divided into glue composite and glue compound, glue composite and divided into water glue, PU oil glue, hot melt adhesive, etc., glue no composite process is mostly direct hot pressing bonding between data or flame incineration composite, the current oil glue laminating machine standard has been implemented.

Features of PU glue laminating machine

On the basis of the conventional glue dot laminating machine, the whole machine has upgraded the functions of active correction, active alignment, active edge stripping, active cloth feeding, active opening, and active blowing of waste edges. The composite material has the advantages of uniform glue, flat compounding, no stretching deformation, no foaming, no wrinkle, softness, better air permeability, regular winding, strong peeling fastness, and water washing resistance.

Advantages of PU glue laminating machine

1. The materials can be bonded together to make the fastness of the composite material better. It can also be used for the bonding of three-layer thin materials to improve production efficiency and reduce production costs.

2. The double rubber groove mesh belt adopts high temperature mesh combined with pressing, so that the composite data is fully exposed to the drying cylinder, improving the drying effect, and making the processed data soft, washable and fastness.

3. The machine is equipped with automatic infrared adjustment equipment, which can prevent the operation error of the mesh belt and extend the service life of the mesh belt.

There are many types of composite materials, especially suitable for cloth patch, woolen tweed, cloth leather, cloth film, sponge patch, sponge patch, fabric patch double-sided or four-sided stretch.

Type knitted fabric and other information fit, winding, unwinding can be based on different data, to select the appropriate equipment, according to the characteristics of different materials, can increase or decrease some equipment, suitable for water-soluble and solvent-based glue coating compound, complete the function of a machine multi-purpose, the amount of glue and the glue style can be adjusted according to the data and practical needs, drum heating can be heated by electricity, steam or heat transfer oil, the width of the machine wheel surface can be specified according to the large width of the practical data, The whole system can be operated and controlled by intelligent PLC program touch screen or mechanical.

Post time: Mar-14-2023