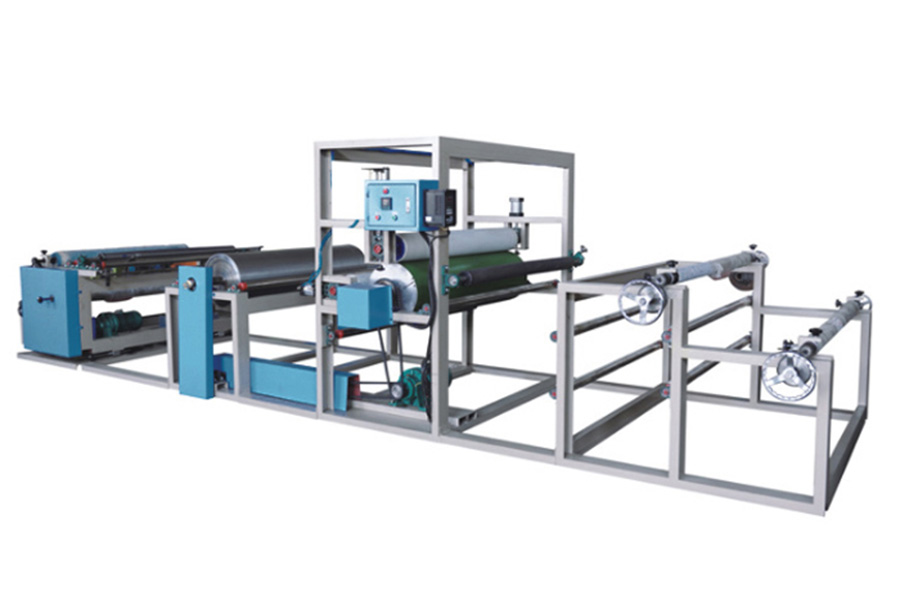

Manufacturing Companies for Spray Glue Laminating Machine - PUR Hot melt glue laminating machine – Xinlilong

Manufacturing Companies for Spray Glue Laminating Machine - PUR Hot melt glue laminating machine – Xinlilong Detail:

The most advanced hot melt adhesive, moisture reactive hot melt glue (PUR), is highly adhesive and environmentally friendly. It can be used for lamination of 99.9% textiles. The laminated material is soft and high temperature resistant. After moisture reaction, the material will not be easily affected by the temperature. Besides, with lasting elasticity, the laminated material is wearresistant, oil resistant and aging resistant. Especially, mist performance, neutral color and other various features of PUR makes medical industry application possible.

Laminating Materials

1. Fabric + fabric:textiles, jersey, fleece, Nylon, Velvet, Terry cloth, Suede,etc.

2. Fabric + films, such as PU film, TPU film, PE film, PVC film, PTFE film,etc.

3. Fabric+ Leather/Artificial Leather,etc.

4. Fabric + Nonwoven

5. Diving Fabric

6. Sponge/ Foam with Fabric/ Artificial Leather

7. Plastics

8. EVA+PVC

Application And Features Of Hot Melt Laminating Machine

1. Applied for gluing and laminating of hot melt glue onto textiles and nonwoven materials.

2. Hot melt adhesives makes possible environmental friendly products and realizes no pollution during the whole process of lamination.

3. It’s of good adhesive property,flexibility,thermostability,non-cracking property at low temperature.

4. Controlled by Programmable Logic Controller system with touch screen and modular designed structure, this machine can be easily and simply operated.

5. Famous brand motors and inverters can be installed for stable machine performance

6. Non-tension unwinding unit makes laminated materials smooth and flat, guaranteeing good bonding effect.

7. Fabric and film openers also makes materials feed smoothly and flatly.

8. For 4-way stretch fabrics, special fabric transmission belt can be installed on the laminating machine.

9. Impregnability of temperature after PUR,lasting elasticity,wear-resistance,oil resistance and anti oxidation.

10. Low maintenance cost and less running noise.

11. When it is applied in lamination of functional waterproof moisture permeable films such as PTFE,PE and TPU, more materials which are waterproofing and insulated, waterproof and protective and oil-water filtering will even be invented.

Main Technical Parameters

|

Effective Fabrics Width |

1650~3850mm/Customized |

|

Roller Width |

1800~4000mm/Customized |

|

Production speed |

5-45 m/min |

|

Demension (L*W*H) |

12000mm*2450mm*2200mm |

|

Heating Method |

heat conducting oil and electric |

|

Voltage |

380V 50HZ 3Phase / customizable |

|

Weight |

about 9500kg |

|

Gross Power |

90KW |

Widely Used In

Product detail pictures:

Related Product Guide:

To consistently enhance the management method by virtue of the rule of "sincerely, fantastic religion and top quality are the base of business development", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for Manufacturing Companies for Spray Glue Laminating Machine - PUR Hot melt glue laminating machine – Xinlilong , The product will supply to all over the world, such as: Salt Lake City, Kuwait, Tunisia, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our products have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!