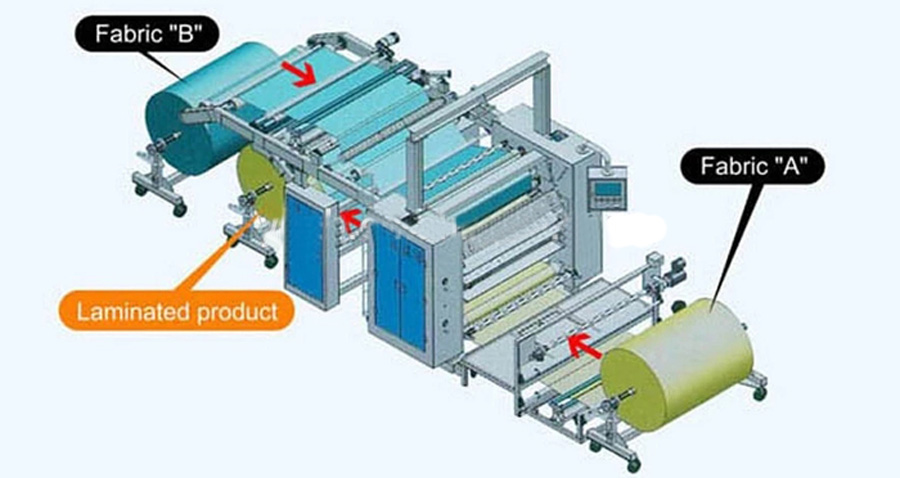

PUR Kub Melt Laminating Tshuab

Hauv kev siv hauv kev lag luam, kub yaj nplaum muab ntau qhov zoo dua li cov kua nplaum raws li cov nplaum.Volatile organic tebchaw raug txo los yog tshem tawm, thiab cov txheej txheem ziab los yog kho yog tshem tawm.Kub yaj nplaum nplaum muaj lub neej ntev ntev thiab feem ntau tuaj yeem muab pov tseg yam tsis muaj kev ceev faj tshwj xeeb.

Qhov zoo tshaj plaws kub yaj nplaum nplaum, noo noo reactive kub yaj kua nplaum (PUR), yog nplaum heev thiab tus phooj ywg ib puag ncig.Nws tuaj yeem siv rau lamination ntawm 99.9% textiles.Cov khoom laminated yog mos thiab kub resistant.Tom qab cov tshuaj tiv thaiv noo noo, cov khoom siv yuav tsis yooj yim cuam tshuam los ntawm qhov kub thiab txias.Tsis tas li ntawd, nrog ntev elasticity, cov khoom laminated yog hnav-resistant, roj resistant thiab aging resistant.Tshwj xeeb tshaj yog, kev ua haujlwm tsis zoo, xim nruab nrab thiab lwm yam nta ntawm PUR ua rau daim ntawv thov kev lag luam kho mob tau.

Tom qab xyoo ntawm kev txhim kho thiab txhim kho, kev ua tau zoo ntawm Xinlilong Technology PUR Kub-Melt Laminating Machine yog qhov zoo tshaj plaws thiab tau sau tseg hauv qab no:

1.Production flow yog yooj yim.

2.Mechanical zog yog qhov tseeb.

3.Mechanism thiab hluav taws xob tswj tau muab tso rau hauv lub txee, vaj huam sib luag tswj tau yooj yim, txuag tib neeg thiab cov nqi sijhawm.

4.Micro-Tension Control muaj peev xwm tuaj yeem ua rau ntau hom ntaub ntaub, uas tuaj yeem ua tiav (Coating & Laminating).

5.Nqa cov ntaub npuag ncaj qha, thiab ua haujlwm tau yooj yim.

6. Hloov cov ntaub ntaub sai sai, thiab txo cov sij hawm ua haujlwm.

7.Modular tsim, mechanism yog yooj yim thiab txij nkawm yooj yim.

8.High stability thiab kev ntseeg siab, tsis tshua muaj nqi ntau lawm.

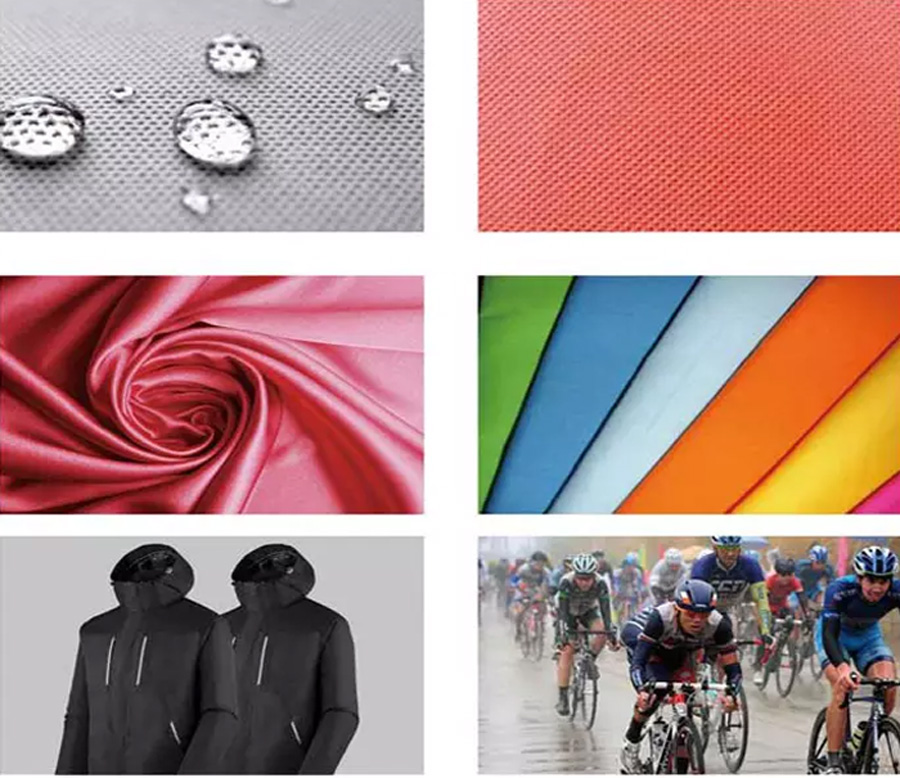

LAMINATING khoom

1. Npuag + ntaub: textiles, tsho, fleece, Nylon, Velvet, Terry ntaub, Suede, thiab lwm yam.

2. Npuag + zaj duab xis, xws li PU zaj duab xis, TPU zaj duab xis, PE zaj duab xis, PVC zaj duab xis, PTFE zaj duab xis, thiab lwm yam.

3. Npuag + Tawv / Artificial Leather, thiab lwm yam.

4. Npuag + Nonwoven

5. Npuag dhia

6. Daim txhuam cev / Ua npuas ncauj nrog ntaub / Artificial tawv

7. Cov yas

8. EVA + PVC

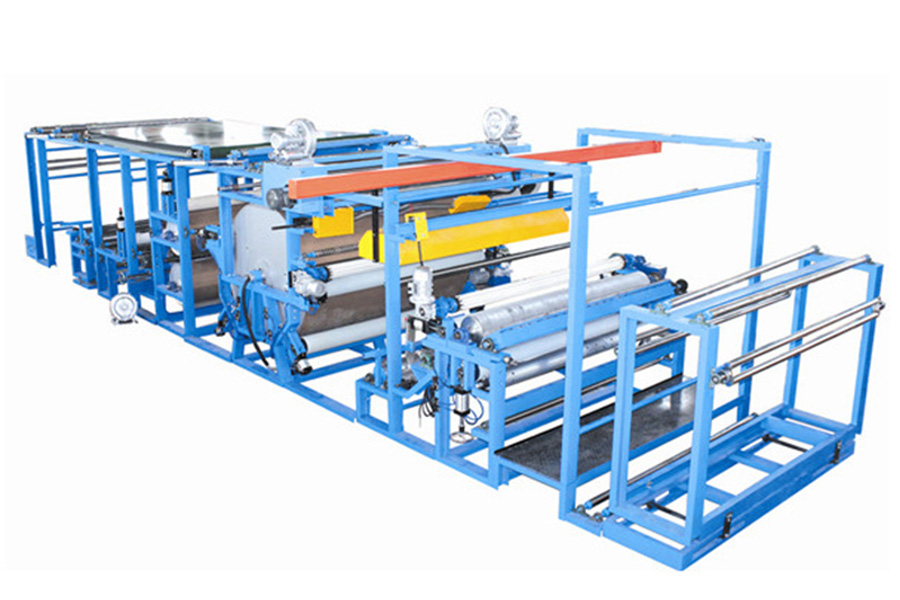

Main Technical Parameters

| Tsis muaj. | Qhov tseem ceeb | Paub meejSpecifications |

| 1 | Main technical parameters | 1) Roller dav yog 1800mm, eua tau zoolaminathauv davyog 1650mm. 2) Feem ntau yog rau laminating fabrics nrog ntaub,tsis-wovencov ntaub ntawv, zaj movie, thiab lwm yam khoom mos thiab lwm yam. 3) Gluing method: kua nplaum hlooved los ntawm gluing roller. 4) Cua sov txoj kev: Thaum tshav kub kub conduction roj rauv. 5)Gluingroller: tus naj npawb ntawm mesh yog raws li cov neeg siv khoom xav tau. 6) Ua haujlwmhauv ceev:0-35m/ min. 7) Fais fab mov: 380V, 50HZ,3 theem. 8) Oil cua sov zog: 12-24KW adjustable. Mmax kub ntawmroj ncigis 180 ° C. 9) Tag nrho cov cuab yeej siv zog:80 kWm. 10)Tshuab Loj(L × W × H): 10200 ×2800 × 3200 hli. |

| 2 | Pub&unwinding ntaus ntawv | 1) Pub&Rolling trolley pawg: A-tsheb, tag nrho3set ib. 2) AMnoj aterialntaus ntawv: ob-log lub tog raj kheejsab raupab pawg sab (nrog PID nrhiav kom paub tswj hom hluav taws xob qhov muag),2 pcsφ88 plating qhia log. 3) Lub rooj ua haujlwm: kev khiav hauj lwm ko taw pedal thiab zaj duab xis winding torque lub cev muaj zog mechanism pab pawg thiab3 pcsφ88 electroplating qhia log. 4) Zaj duab xis noj: zaj duab xisxathav duab thiab hu rau φ160 roj hmab log * 1HP hloov pauv zaus tsav thiab1pc uazaj duab xis kis tau tus mob. 5) Pab pawg tswj kev nruj ua ntej sizing: φ75 txhuas log ob-log nro seev cev pab pawg, nruab nrog precision pneumatic piping tivthaiv pawg. 6) IBMnoj aterialntaus ntawv: φ160 roj hmab kis tau tus mob log * 2HP sib txawv zaus tsavob npauglog cylinder opposite sab pawg, 3 pcsφ88 plating qhia log. 7) Strip unfolding log ua ntej gluing: φ125 strip unfolding log. 8) Unfolding log ua ntejlaminating: Cov khoom siv yog siv rau pem hauv ntej sawb unfolding log thiab 0.5HP zaus conversion tsav thiab B cov ntaub ntawv yog siv rau pem hauv ntej txhuas ntawv unfolding log. |

| 3 | Pwm kub tshuab | 1) Pwm kub tshuab: precision computer adjustable roj kub 0-180 ° C,total powe r yog18 kwv. |

| 4 |

Glue yajtshuab

| 1) Rauyajcov kua nplaum: ib txheej ntawm 200KGkua nplaumtshuab yajnrog55 hlipressure phajthiab kua nplaumtube (tiv thaiv scalding), LCD zaub,yooj yim raumoua ve. |

| 5 | Gluing ntaus ntawv | 1) Gluing unit:φ250 Gluingqauvlub log,2HP zaus conversion,lub ntsiab ceev tswj tsav saw iav thiab teb sib koom ua ke thiab cov kabmob thiab nuv riam hom muab tshuaj txhuam phaj thiab pneumatic lifting mechanism pawg thiabφ250 rov qab siab lub log, nrog hluav taws xob hloov kho qhov sib txawv ntawm pawg tswj.Pebpcs gluingroller (thov paub meejtus qauvua ntej). 2) Gluing cov menyuam hloovcrane: Ib leeg-khiav 500KG ib leeg-ua haujlwm nqa crane pawg rauqhov gluinghloov lub log. |

| 6 | Laminatingntaus ntawv | 1) Laminatingchav tsev: laminated electroplating ntugφ250 * 2HP hloov pauv zaus tsav thiabφ250 roj hmab rov qab siab log thiabφ250 xovxwm-haum daim iav menyuam thiab pneumatic lifting mechanism pab pawg, nrog hluav taws xob tes hloov qhov sib txawv zaub tswj. 2) Cooling teeb:φ250 electroplating txias log * 2 teebnrogpob qij txha thiab bearings. |

| 7 | Cov khoom siv winding | 1) Pab pawg pub: ib khub ntawm lub caij nplooj ntoos hlav splitting yob. 2) Tension pawg ua ntej winding:φ100 txhuas log nro pawg, nruab nrog precision pneumatic piping tivthaiv pawg, txhuas ntawv unfolding log ua ntej winding. 3) Surface winding pawg:φ160 roj hmab kis tau tus mob log * 2HP sib txawv zaus tsav thiab pneumatic lifting mechanism pab pawg neeg thiab txhuas ntawv unrolling log ua ntej winding (tsis kis tau tus mob) thiab kauv caj npab rov qab siab precision pneumatic piping tivthaiv pawg,φ88 plating phau ntawv qhiawluj* 2pcs. |

| 8 | Electronic tswj qhov system | 1) Tib neeg-tshuab interface kov npo ua haujlwm, PLC tswj. 2) PLC tswj thiab tswj moduleis raumTaiwan Yonghong. 3) Kov tswj lub vijtsamlushauv lus Askiv&Suav. 4) Tswj hom: Tag nrho lub tshuab ua haujlwm synchronously thiab centrally tswj los ntawm inverter.Kev ua haujlwm yog yooj yim thiab yooj yim, thiab kev ua tau zoo yog txhim khu kev qha. 5) Lub cev muaj zog reducer hom: Siemens. 6) txwv hloovhom:CKHOOM. 7) Pneumatic Cheebtsamhom: Taiwan Yadeke. 8) Digital ntsuas kub tswj ntsuashom: AOYI. 9) Vector Inverterhom: Huihua. 10) Kev tswj hwm qhov system: all parameters yog teem thiab dynamically tso tawm kom pom ntawm lub vijtsam kov. 11) Thaum lub tshuab tag nrho qhib, tag nrho cov tsav tsheb yuav raug txiavkov, txiav txiav thaum lub tshuab nres, thiabkujmuaj kev ua haujlwm ntawm phau ntawv qhib thiab kaw. 12) Lub hauv paus tseem ceeb tswj txee yog nyob rau hauv nruab nrab ntawm lub tshuab, nrog rau kev khiav hauj lwm zaub thiab cov nyees khawm ntawm lub winding. 13) Tswj cable: tiv thaiv kev cuam tshuam cable, txuas nrog daim ntawv lo, lub thawv cable, ua kom zoo nkauj rau kev saib xyuas yooj yim. |

| 9 | Mechanical qhov chaw&khib | 1) Hlau phaj: GB-45. 2) Profile: GB channel steel, GB square tubehlau. 3) Kem: 120 * 120 * 6 square tube,srooj thiab anti-seismic. 4) Beam: 120 * 120 * 6 square tube,srooj thiab anti-seismic. 5) Structure: Tag nrho lub tshuab txais cov qauv qauv thiab yog detachable thiab thauj. 6) Qhia cov menyuam: aluminium alloy,by anti-oxidation kev kho mob, anti-scratch thiab khawb kev kho mob, HV700 anode kev kho mob, sib npaug kev kho mob, unbalance tus nqi tsawg tshaj li 2g. |

| 10 | Tshuabpleev xim | 1) Putty 2) Anti-xeb primer 3) Nto xim xim: beige (los yog xim xaiv los ntawm tus neeg siv khoom). |

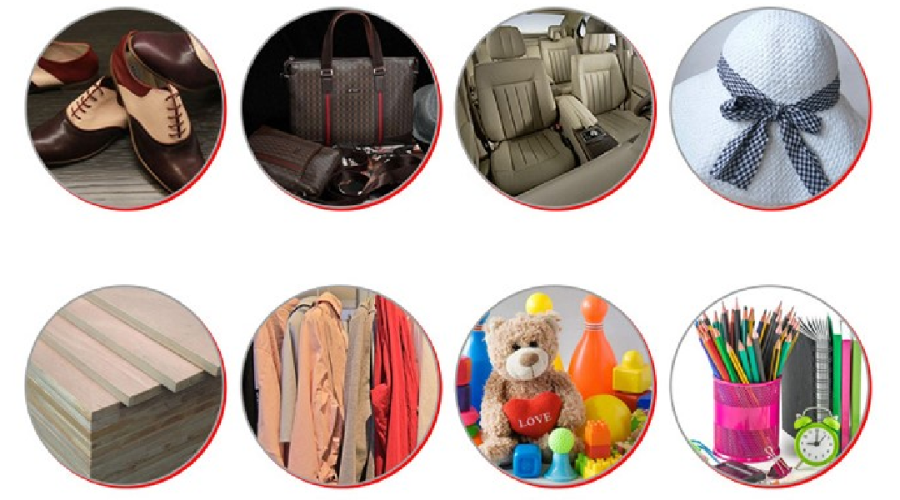

Daim Ntawv Thov Thiab Nta Ntawm Kub Melt Laminating Tshuab

1. Siv rau gluing thiab laminating ntawm kub yaj kua nplaum rau textiles thiab nonwoven cov ntaub ntawv.

2. Kub yaj nplaum nplaum ua rau ib puag ncig tus phooj ywg cov khoom thiab paub tias tsis muaj kuab paug thaum lub sij hawm tag nrho cov txheej txheem ntawm lamination.

3. Nws yog cov khoom nplaum zoo, yoog raws, thermal stability, tsis muaj qhov tawg ntawm qhov kub thiab txias.

4. Tswj los ntawm Programmable Logic Controller system nrog kov npo thiab cov qauv tsim qauv, lub tshuab no tuaj yeem ua tau yooj yim thiab ua haujlwm yooj yim.

5. Lub npe nrov motors thiab inverters tuaj yeem ntsia tau rau kev ua haujlwm ruaj khov ntawm lub tshuab

6. Non-tension unwinding unit ua rau cov ntaub ntawv laminated du thiab tiaj tus, lav zoo kev sib raug zoo.

7. Npuag thiab zaj duab xis openers kuj ua rau cov khoom noj smoothly thiab flatly.

8. Rau 4-txoj kev stretch fabrics, tshwj xeeb ntaub kis tau tus mob txoj siv yuav raug ntsia rau ntawm lub tshuab laminating.

9. Impregnability ntawm kub tom qab PUR, kav ntev elasticity, hnav-tiv taus, roj kuj thiab anti oxidation.

10. Tsawg tus nqi txij nkawm thiab tsis tshua muaj suab nrov.

11. Thaum nws yog siv rau hauv lamination ntawm kev ua haujlwm tsis muaj dej noo permeable films xws li PTFE, PE thiab TPU, ntau cov ntaub ntawv uas yog waterproofing thiab insulated, waterproof thiab tiv thaiv thiab roj-dej filtering yuav txawm invented.

Siv dav hauv

Siv dav hauv factories, kev lag luam, khoom vaj khoom tsev, kev tsim kho, warehouses, tshav dav hlau, chaw nres tsheb roj thiab lwm qhov chaw.peb tuaj yeem tsim cov khoom tsim nyog rau cov neeg siv khoom raws li qhov xav tau ntawm ntau yam kev lag luam.

FAQ

Koj puas yog lub Hoobkas?

Yog lawm.Peb yog cov kws tshaj lij tshuab tsim khoom tshaj 20 xyoo.

Yuav ua li cas txog koj qhov zoo?

Peb muab cov khoom zoo tshaj plaws thiab tus nqi tsim nyog rau txhua lub tshuab nrog kev ua haujlwm zoo, ruaj khov ua haujlwm, tsim kev tshaj lij thiab siv lub neej ntev.

Kuv tuaj yeem kho lub tshuab raws li peb xav tau?

Yog lawm.Kev pabcuam OEM nrog koj tus kheej lub logo lossis cov khoom lag luam muaj.

Muaj pes tsawg xyoo koj export lub tshuab?

Peb tau xa tawm cov tshuab txij li xyoo 2006, thiab peb cov neeg siv khoom tseem ceeb nyob hauv Egypt, Qaib ntxhw, Mexico, Argentina, Australia, USA, India, Poland, Malaysia, Bangladesh thiab lwm yam.

Koj qhov kev pab cuam tom qab muag yog dab tsi?

24 teev nyob ib ncig ntawm lub moos, 12 lub hlis warranty & kev tu lub neej.

Kuv tuaj yeem nruab thiab khiav lub tshuab li cas?

Peb muab cov lus qhia ntxaws ntxaws thiab cov yeeb yaj kiab ua haujlwm.Kws ua haujlwm tseem tuaj yeem mus txawv tebchaws rau koj lub Hoobkas los nruab lub tshuab thiab ua haujlwm rau koj cov neeg ua haujlwm.

Kuv puas yuav pom lub tshuab ua haujlwm ua ntej kev txiav txim?

Txais tos tuaj xyuas peb lub Hoobkas txhua lub sijhawm.