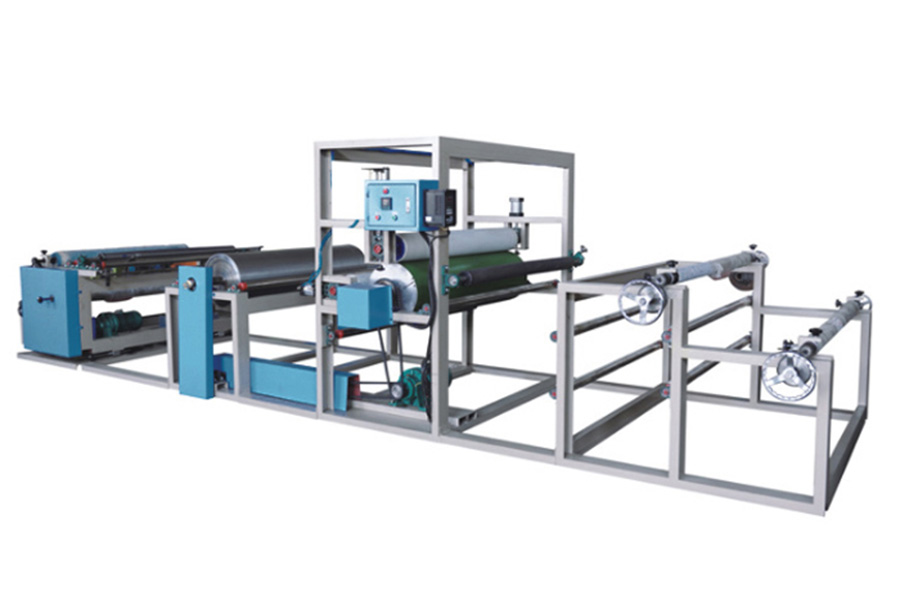

Free sample for Multi Fuction Hot Melt Glue Laminating Machine - Fabric to film laminating machine – Xinlilong

Free sample for Multi Fuction Hot Melt Glue Laminating Machine - Fabric to film laminating machine – Xinlilong Detail:

The feeding device and edge position control mechanism use simple and fast design and have the features of power-saving, space-saving and nimble operation.

We can design and manufacturer laminating machines according to customer’s different requirements, even for a vary of cloth materials or thin films, the processes for different sizes, different operation temperatures and different tension limit are all could be completed with the best solutions.

Xinlilong has professional experience of more than 20 years for manufacturing laminating machines, could satisfy a vary of laminating requirements to cloth fabrics and thin films etc.

Structure

Fabric to Film Laminating Machine

1. Applied for gluing and laminating of fabric, nonwoven, textile, waterproof, breathable films and etc.

2. Aided by PLC program control and man-machine touch interface, easy to operate.

3. Advanced edge alignment and scothing devices, this machine increases the degree of automation, saves labor costs, relieves labor intensity, and enhances production efficiency.

4. With PU glue or solvent based glue, the laminated products have good adhesive property and touch well. They are washable and dry-cleanable. Due to the glue is in the point form when laminating, the laminated products are breathable.

5. Efficient cooling device enhances the lamination effect.

6. Sewing cutter is used to cut the raw edges of the laminated materials.

Laminating Materials

1.Fabric + fabric:textiles, jersey, fleece, Nylon, Velvet, Terry cloth, Suede,etc.

2.Fabric + films, such as PU film, TPU film, PE film, PVC film, PTFE film,etc.

3.Fabric+ Leather/Artificial Leather,etc.

4.Fabric + Nonwoven

5.Sponge/ Foam with Fabric/ Artificial Leather

Main Technical Parameters

|

Effective Fabrics Width |

1600~3200mm/Customized |

|

Roller Width |

1800~3400mm/Customized |

|

Production speed |

10-45 m/min |

|

Demension (L*W*H) |

11800mm*2900mm*3600mm |

|

Heating Method |

heat conducting oil and electric |

|

Voltage |

380V 50HZ 3Phase / customizable |

|

Weight |

about 9000kg |

|

Gross Power |

55KW |

Widely Used In

Product detail pictures:

Related Product Guide:

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Free sample for Multi Fuction Hot Melt Glue Laminating Machine - Fabric to film laminating machine – Xinlilong , The product will supply to all over the world, such as: Kyrgyzstan, Sevilla, belarus, We integrate design, manufacture and export together with more than 100 skillful workers, strict quality controlling system and experienced technology.We keep long term business relationships with wholesaler and distributors form more than 50 countries, such as USA, UK, Canada, Europe and Africa etc.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!