China Film Laminating Machine - Double burner flame lamination machine – Xinlilong

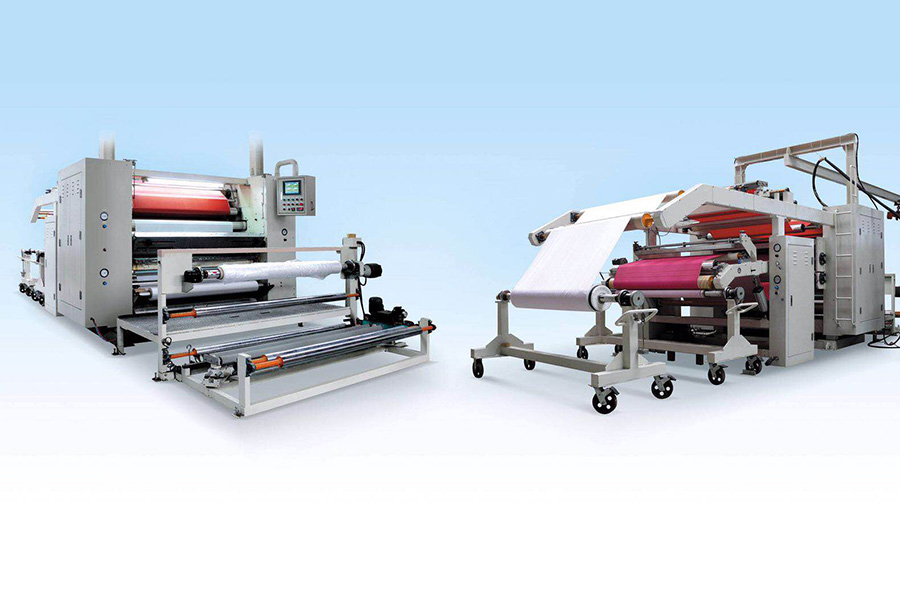

China Film Laminating Machine - Double burner flame lamination machine – Xinlilong Detail:

Flame lamination is a process that adheres material to one side of the fire retardant foam or EVA. Pass the foam or EVA over a flame produced by a flare roller, creating a thin layer of sticky stuff on the surface of one side of the foam or EVA.Then, quickly press the material against the sticky stuff of the foam or EVA.

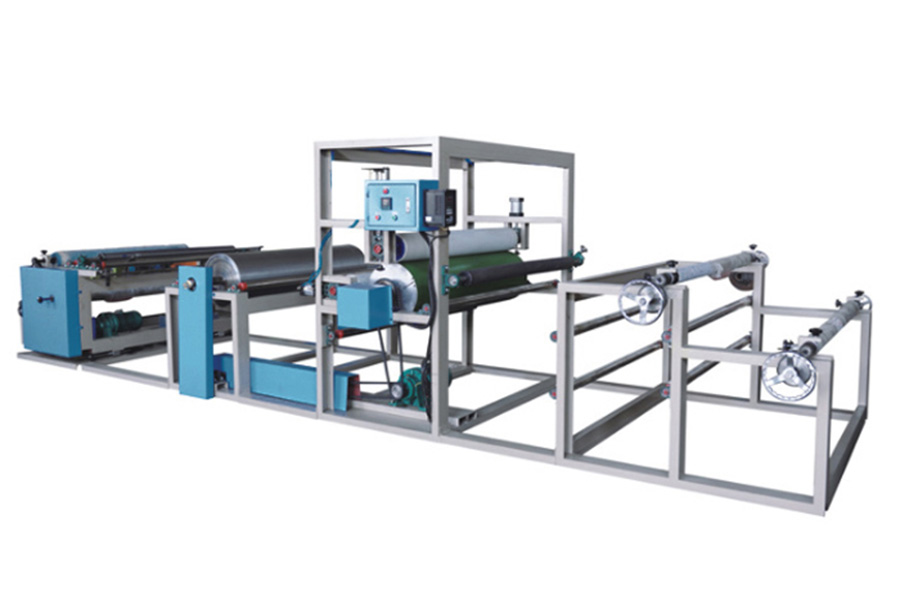

Working Process

1. Flame lamination is a process that adheres material to one side of the fire retardant foam or EVA.

2. Pass the foam or EVA over a flame produced by a flare roller, creating a thin layer of sticky stuff on the surface of one side of the foam or EVA.

3. Then, quickly press the material against the sticky stuff of the foam or EVA.

Flame Lamination Machine Features

1. Gas Type: Natural Gas or Liquefied Gas.

2. The water cooling system well enhances the lamination effect.

3. The air exhaust diaphragm will exhaust the odor.

4. Fabric spreading device is installed to make the laminated material smooth and neat.

5. The strength of the bonding depends on the material and the foam or EVA selected and the processing conditions.

6. With high integrity and long term adhesive durability, the laminated materials touch well and is dry washable.

7. Edge tracker, tensionless fabric unwinding device, stamping device and other auxiliary equipment can be optionally installed.

Main Technical Parameters

|

Model |

XLL-H518-K005B |

|

Burner Width |

2.1m or customised |

|

Burning Fuel |

Liquefied natural gas (LNG) |

|

Laminating speed |

0~45m/min |

|

Cooling method |

water cooling or air cooling |

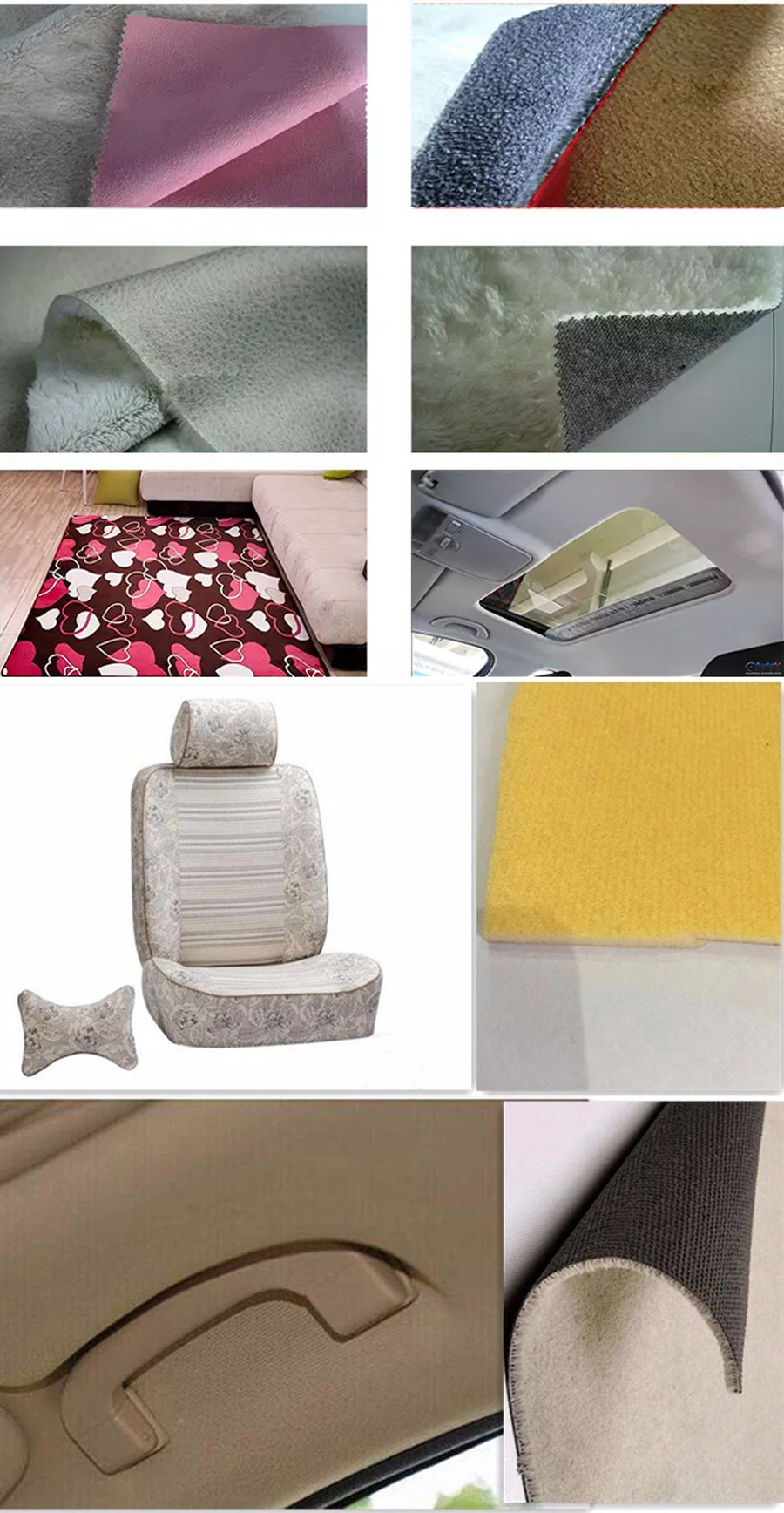

Widely Used In

Automotive industry (interiors and seats)

Furniture industry (chairs, sofas)

Footwear industry

Garment industry

Hats, gloves,bags, toys and etc

FAQ

Are you a factory?

Yes. We’re professional machinery manufacturer over 20 years.

How about your quality?

We supply excellent quality and reasonable price for all machines with Perfect performance, Stable working, Professional design and Long life use.

Can I customize the machine according to our requirement?

Yes. OEM service with your own logo or products are available.

How many years you export the machine?

We exported machines since 2006, and our main customers are in Egypt, Turkey, Mexico, Argentina, Australia, USA, India, Poland, Malaysia, Bangladesh etc.

What is your after-sales service?

24 hours around the clock, 12 months warranty & lifetime maintenance.

How can I install and operate the machine?

We offer detailed English instruction and operation videos. Engineer can also go abroad to your factory to install the machine and traning your staff to operation.

Shall I see the machine working before order?

Welcome to visit our factory for any time.

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for China Film Laminating Machine - Double burner flame lamination machine – Xinlilong , The product will supply to all over the world, such as: Vietnam, Rwanda, India, We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and perfect service . We also warmly welcome customers to visit our company and purchase our products.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.