Automatic flame bonding machine

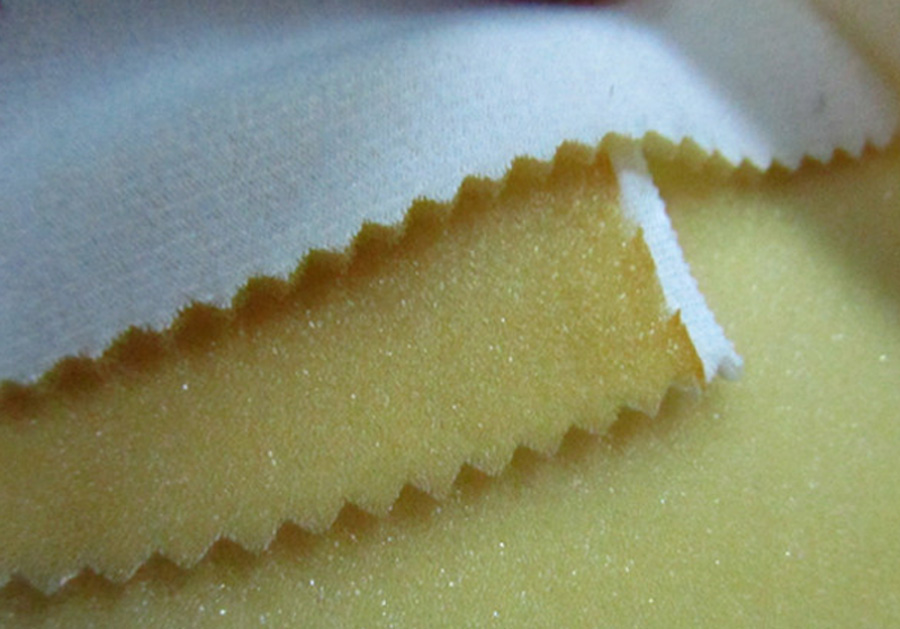

Our automatic flame bonding machine is suitable for the laminating or pressing of thermo-fusible products, such as PU foam and PE, with synthetic or natural materials.

In order to improve the production capacity, our machine is use two burners in line (instead of one) thus obtaining the lamination of three materials at one time.

Taking into account its considerable production speed, our machine can be equipped with some additional accessories customrized that will allow a continuative use, by introducing appropriate accumulating systems.

Flame Lamination Machine Features

1. It adopts advanced PLC, touch screen and servo motor control, with good synchronization effect, no tension automatic feeding control, high continuous production efficiency, and the sponge table is used to be uniform, stable and not elongated.

2. The three-layer material can be combined in one time through the double-fired simultaneous combustion, which is suitable for mass production. Domestic or imported fire platoons can be selected according to the product requirements.

3. The composite product has the advantages of strong overall performance, good hand feeling, water washing resistance and dry cleaning.

4. special requirements can be customized as needed.

Main Technical Parameters

|

Model |

XLL-H518-K005C |

|

Burner Width |

2.1m or customised |

|

Burning Fuel |

Liquefied natural gas (LNG) |

|

Laminating speed |

0~45m/min |

|

Cooling method |

water cooling or air cooling |

Widely Used In

Automotive industry (interiors and seats)

Furniture industry (chairs, sofas)

Footwear industry

Garment industry

Hats, gloves,bags, toys and etc